English

English

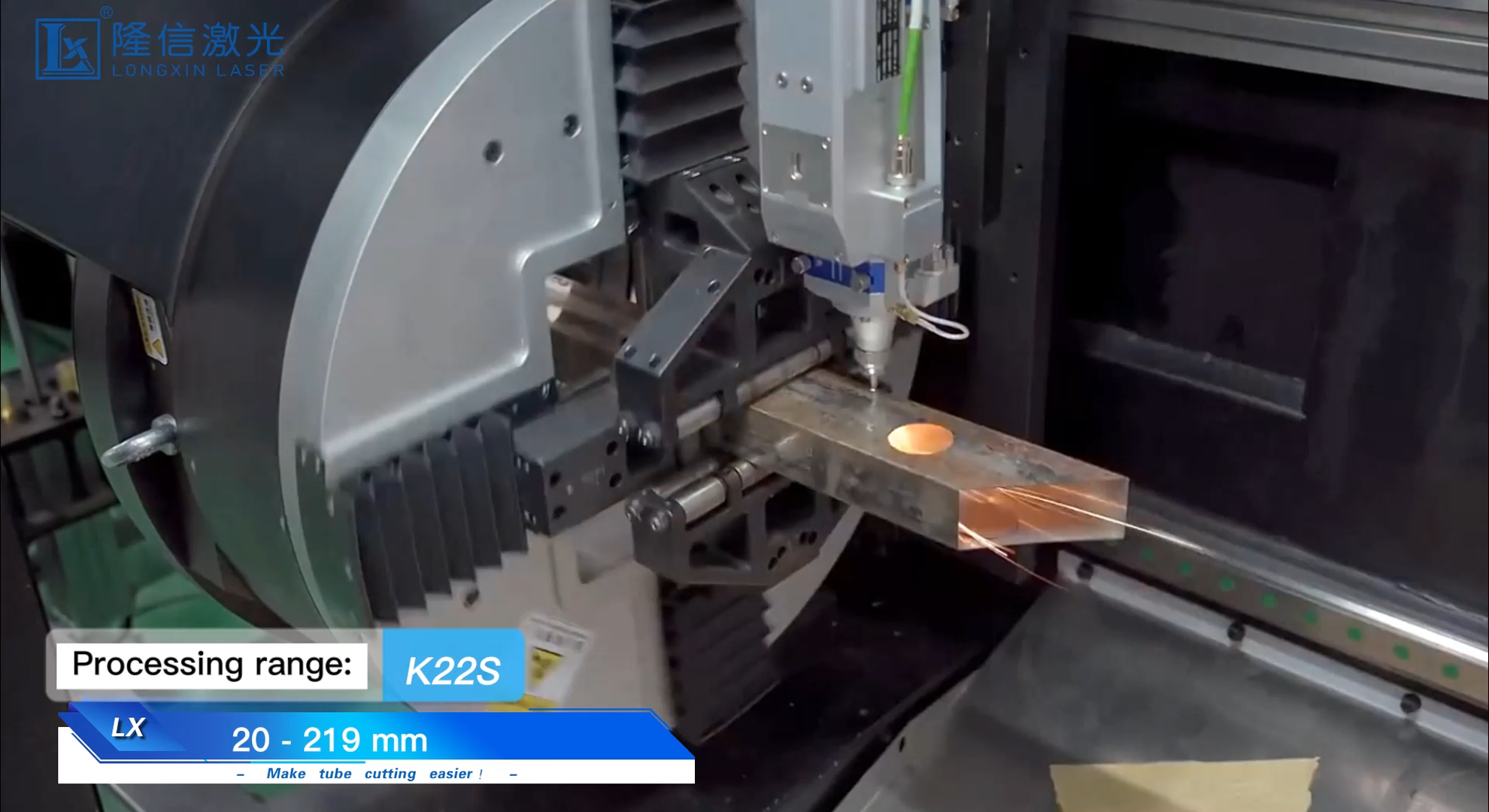

Demystifying Laser Pipe Cutting: Everything You Need to Know

Laser pipe cutting is a versatile and precise cutting method that utilizes laser technology to cut various types of pipes with exceptional accuracy. Here's everything you need to know about laser pipe cutting:

Laser pipe cutting involves the use of a high-powered laser beam that is directed onto the pipe's surface. The laser beam melts or vaporizes the material along the intended cutting path, creating a narrow kerf. The pipe is rotated or moved along its axis while the laser beam remains stationary or moves in a synchronized manner. This process allows for precise and clean cuts.

Laser pipe cutting machines typically use two types of laser sources: CO2 lasers and fiber lasers. CO2 lasers are ideal for cutting non-metallic materials and thin metal pipes, while fiber lasers are well-suited for cutting metals such as steel, stainless steel, and aluminum. The choice of laser source depends on the material and thickness of the pipe being cut.

1. Precision: Laser cutting provides high accuracy and tight tolerances, allowing for intricate and complex designs.

2. Versatility: Laser pipe cutting can handle a wide range of pipe shapes, sizes, and materials, including round, square, rectangular, and oval pipes.

3. Speed and Efficiency: Laser cutting machines operate at high speeds, resulting in faster production cycles and shorter lead times.

4. Clean Cuts: Laser cutting produces clean, burr-free cuts, reducing the need for post-cutting finishing processes.

5. Automation: Laser pipe cutting machines can be integrated into automated systems, improving productivity and reducing manual labor.

6. Non-contact Cutting: Laser cutting is a non-contact process, minimizing the risk of material deformation or damage.

7. Flexibility: Laser pipe cutting allows for the cutting of both straight and contoured pipe sections, enabling complex geometries.

1. Material Selection: Laser pipe cutting machines can handle various materials, but the cutting parameters may vary depending on the material type and thickness. Different materials require specific laser sources and cutting configurations.

2. Laser Power and Cutting Speed: The laser power and cutting speed need to be optimized based on the material thickness, desired cut quality, and productivity requirements.

3. Assist Gas Selection: The choice of assist gas, such as oxygen, nitrogen, or compressed air, depends on the material being cut. The assist gas helps in the cutting process by blowing away molten material and reducing heat-affected zones.

4. Fixturing and Support: Proper support and fixturing of the pipe during cutting are essential to maintain stability and prevent distortion.

1. Automotive: Exhaust systems, chassis components, and roll cages.

2. Construction: Structural components, handrails, and decorative elements.

3. HVAC (Heating, Ventilation, and Air Conditioning): Ductwork and pipe assemblies.

4. Furniture: Metal frames, table legs, and tubing for upholstery.

5. Aerospace: Tube assemblies, engine components, and aircraft structures.

6. Energy: Pipelines, power generation equipment, and renewable energy components.

Laser pipe cutting technology continues to evolve, offering increased precision, speed, and versatility. It provides manufacturers with a reliable and efficient cutting method, enabling the production of high-quality pipe components for various industries.