English

English

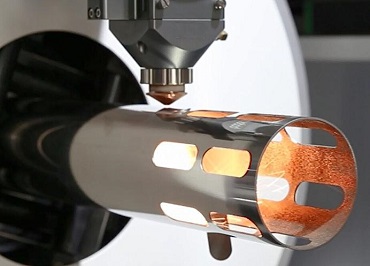

No matter how good the equipment is, there will be all kinds of failures. Next, Longxin laser manufacturer will introduce several maintenance methods for common failures of optical fiber laser cutting head:

1. The objective lens is dirty

* wipe the cotton swab with pure water;

* if the dirt is serious, the whole body can be soaked with purified water and detergent without a bare head, and then dried after rinsing. This method can thoroughly clean the surface under the objective lens.

2. Object mirror grinding

* if slightly worn, use a cotton swab dipped in toothpaste and rinse with clean water;

* in case of severe abrasion, the intact object lens components can be removed from the same or similar old optical head;

* switch to the new cutting head of the same model.

3. Sinking of the objective assembly

* adjust the objective lens to the correct position and fix it. After heating the plastic movable bracket of the objective lens with the electric hair dryer at low temperature, remove the fixator after natural cooling, and then repair it;

* remove the intact object lens assembly from the same or similar old optical head;

* switch to the new cutting head of the same model.