English

English

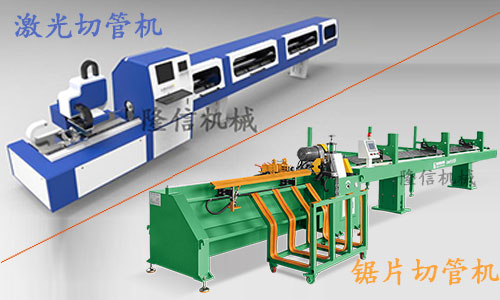

From the continuous innovation process of high-speed machining machines, it can be seen that the laser cutting machine has advantages in high-speed performance, processing diversity and processing precision in making full use of the achievements in the current technical field.

High speed performance:

The principle of the laser pipe cutting machine uses a metal laser with a xenon lamp as an excitation source to output a laser beam of high energy density, and focuses on the surface of the workpiece, so that the area irradiated by the spot on the workpiece is locally melted and vaporized instantaneously. It can reach n times the speed of the saw blade cutter. It is a high-tech equipment integrating laser technology, numerical control technology and automation technology.

Processing sample:

The laser pipe cutting machine can perform deformation-free cutting, opening, beveling, 45-degree cutting, butt-cutting, beveling and cutting, hollowing and punching on any hardness material such as steel plate, stainless steel, aluminum alloy plate and hard alloy. Coherent wire cutting. In particular, any pattern can be processed. The saw blade cutter can only serve as a cutting part in the processing of the pipe.

Precision:

Compared with the saw blade cutting machine, the laser cutting machine has much higher precision, just as different materials may undergo slight deformation during processing. It can be flexibly adjusted according to these deformations to ensure accuracy, which is also a lot. Traditional processes such as saw blade cutting machines are not available.