English

English

When it comes to manufacturing processes, laser cutting has revolutionized the industry. This advanced technology employs a high-powered laser to cut through various materials, producing accurate and consistent results. Laser cutting offers numerous advantages over traditional cutting methods, making it a popular choice for various industries. Let's delve into the benefits of laser cutting in more detail.

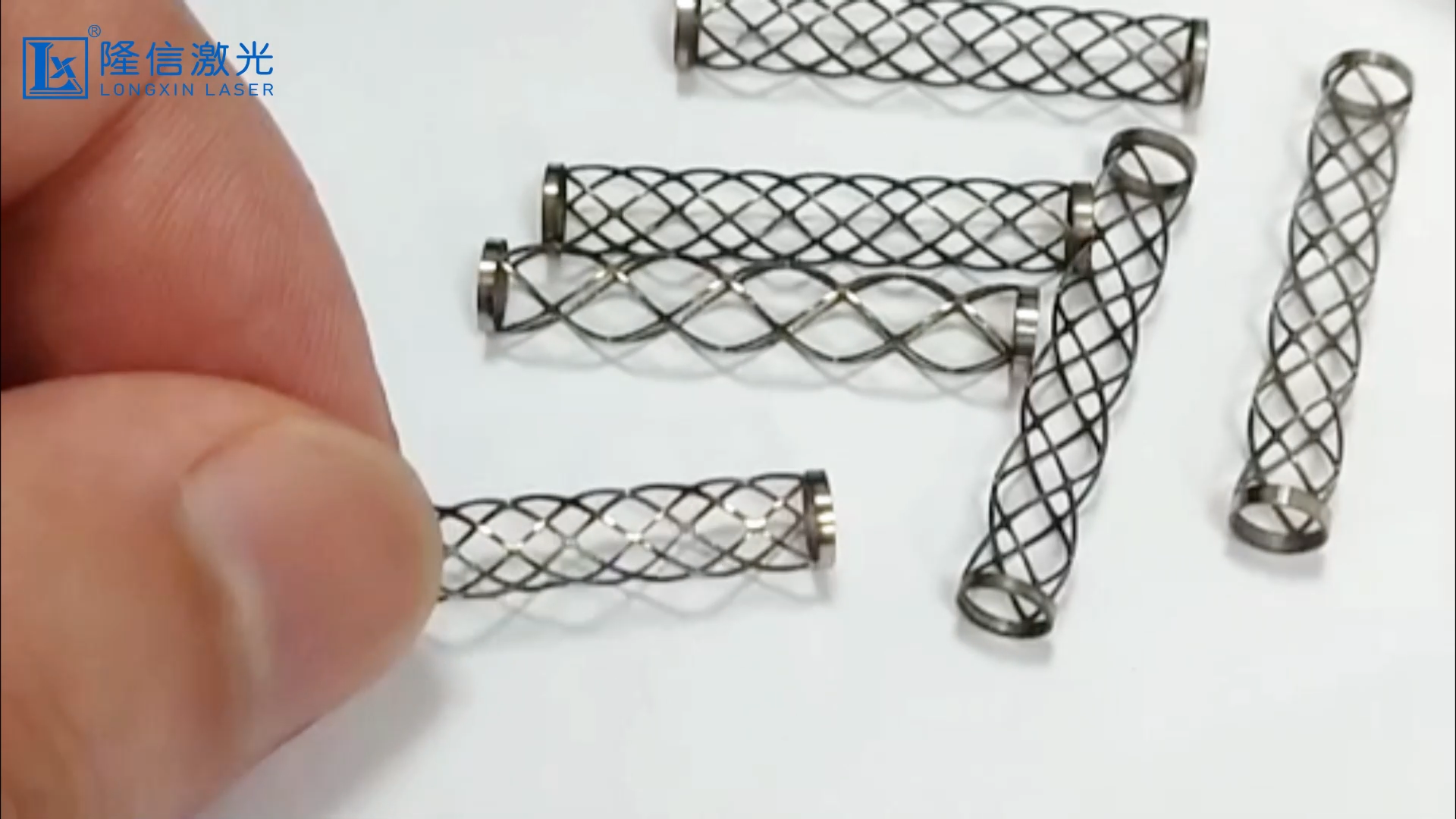

One of the significant advantages of laser cutting is precision. Laser cutting is exceptionally accurate, allowing for intricate and complex designs to be cut with ease. The laser beam can cut through the material with pinpoint accuracy, making it possible to create intricate shapes and patterns with minimal waste. Additionally, the laser beam can be controlled with precision, allowing for consistent results every time. This makes it an excellent option for industries that require precision, such as the medical and aerospace industries.

Laser cutting is incredibly fast, enabling manufacturers to produce parts quickly and efficiently. Unlike traditional cutting methods, which require multiple passes to achieve the desired result, laser cutting can cut through materials in a single pass. This means that production times are significantly reduced, which can lead to increased productivity and profitability. Laser cutting can also handle multiple materials, including metals, plastics, and wood, making it a versatile option for many industries.

Another advantage of laser cutting is its automation capabilities. Modern laser cutting machines can be fully automated, allowing for continuous production with minimal intervention. This means that once the machine is set up, it can run for hours or even days without the need for manual intervention. Additionally, automated laser cutting machines can be programmed to perform a range of tasks, such as cutting, engraving, and marking, making them an incredibly versatile option.

Laser cutting generates less waste than traditional cutting methods, reducing material costs and minimizing environmental impact. Because the laser beam is incredibly accurate, there is minimal material waste, which can significantly reduce costs. Additionally, laser cutting produces fewer secondary operations, such as deburring, reducing the amount of waste produced during the manufacturing process.

Finally, laser cutting offers lower energy costs compared to traditional cutting methods. Laser cutting machines use less energy to operate, reducing energy consumption and costs. Additionally, laser cutting machines can be programmed to optimize material usage, further reducing energy consumption and costs.

In conclusion, laser cutting offers numerous advantages over traditional cutting methods. Its precision, speed, automation capabilities, efficiency, and sustainability make it an excellent option for various industries. With its ability to produce accurate and consistent results quickly and efficiently, laser cutting has revolutionized the manufacturing industry, and its popularity is only set to increase in the future.