English

English

Laser cutting has become the technical development direction of modern metal processing because of its high speed, high precision, high quality, energy saving and environmental protection. Laser cutting machines account for 32% of the market in laser processing applications. The biggest difference between laser cutting and other cutting methods is its high speed, high precision and high adaptability. At the same time, it has the advantages of fine slitting, small heat affected zone, good quality of cutting surface, no noise during cutting, good verticality of slit edge, smooth trimming, easy automatic control of cutting process. When laser cutting sheets, no mold is needed, which can replace some punching processing methods that require complex large molds, which can greatly shorten the production cycle and reduce costs.

Laser processing in Automotive Industry

1. The automotive industry is a highly concentrated industry with high technology.

2. As an advanced manufacturing method, in the developed industrial countries of Europe and America, 50%~70% of auto parts are processed by laser processing.

3. The automotive industry mainly uses laser welding and laser cutting as the main processing methods.

Laser technology in the automotive industry

Laser processing has many advantages such as low thermal impact and small material deformation.

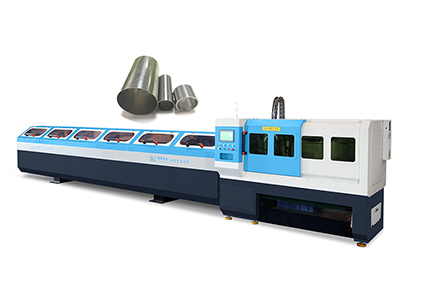

(lx laser pipe cutting machine )

video : https://youtu.be/3x3RGJXtyCc