English

English

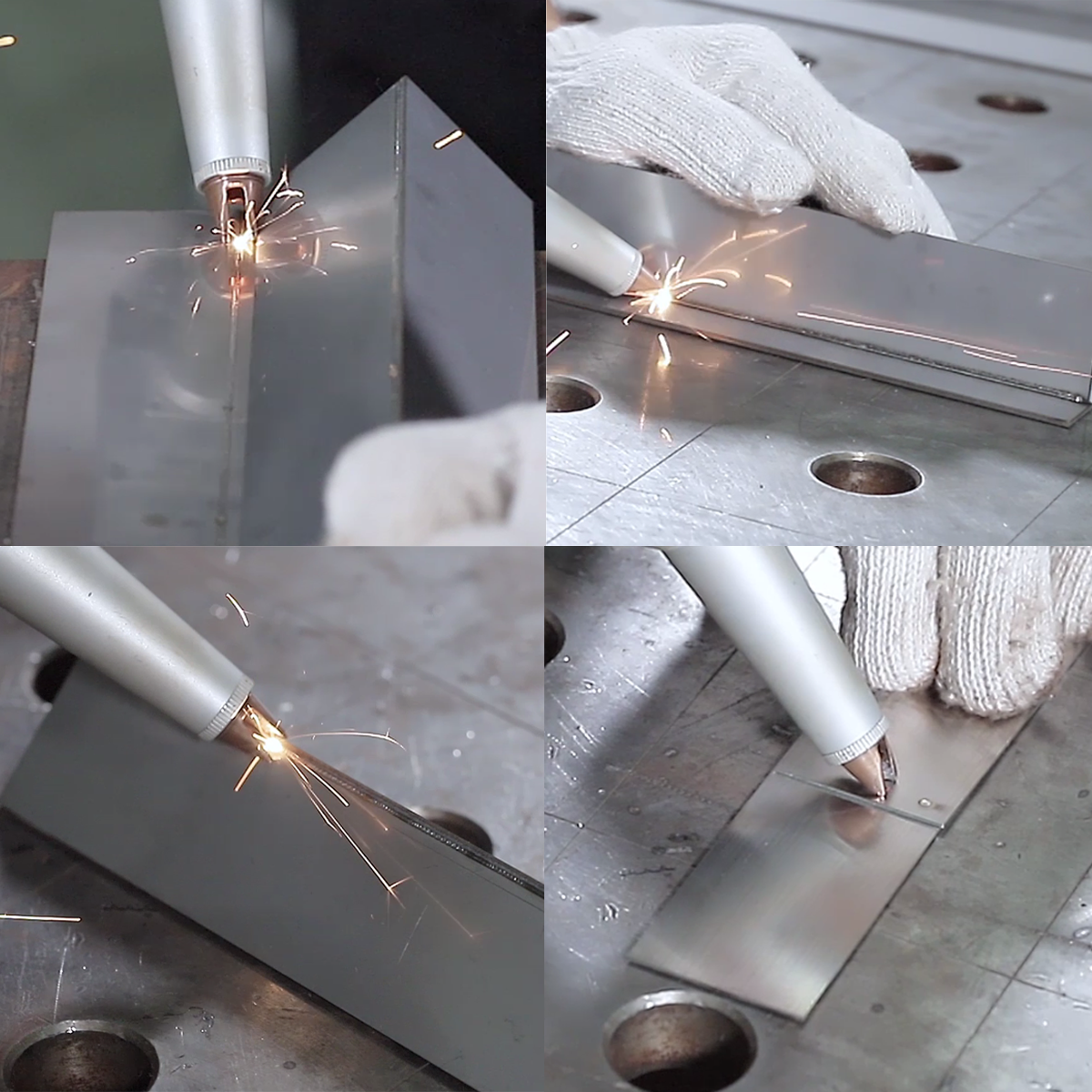

With the development of laser technology, more and more fields can use laser to improve our productivity.Today , let's learn more about laser in the welding -Hand welding

Laser welding theory:

Concentrates the laser beam in a small area, and in a very short time, forms a local heat source area with high energy concentration in the welded part, so that the welded part melts and forms firm solder joints and welds.

Compared with other welding methods, laser hand welding has the following advantages

1. Convenient and flexible use: Hand-held welding, free and flexible, wide reachable range, welding torch 0.8KG, long-lasting and not tired.

2. Easy operation: Hand-held welding products are easy to use, with 0 experience in one day, which can solve the difficult problem of recruiting welders.

3. High welding efficiency: The welding speed of the product is fast, which is more than 3 times that of argon arc welding, which can save 2 welding workers.

4. The weld does not need to be polished: continuous welding mode, smooth welding without fish scales, beautiful welding without scars, less follow-up grinding process.

5. No consumables for welding: Welding can be completed without filling wire.

6. Perfect welding effect: The welding affected area is small, the welding quality is good, and the workpiece deformation is small.

7. High energy efficiency conversion: the photoelectric conversion efficiency of the laser is as high as 30%, and the energy consumption is lower.

The applicable process of hand welding is as follows.

Benefits of handheld welding to customers Process quality improvement, efficiency and management improvement, brand promotion.