English

English

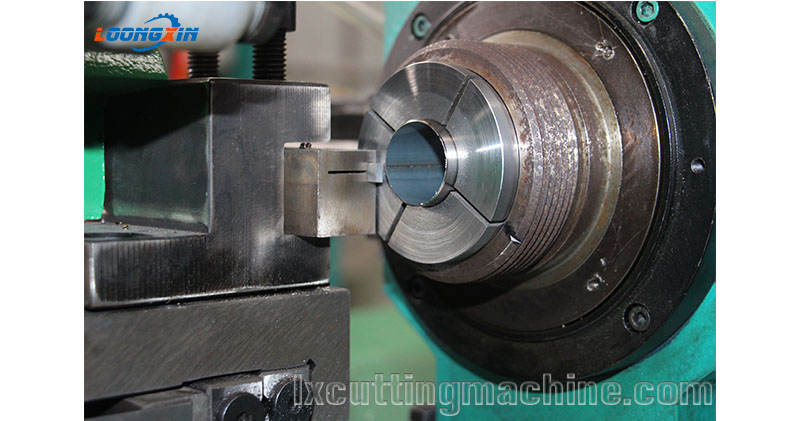

Instrumentation lathe automatic pipe cutting machine manufacturer Longxin Machinery knows well: Quality is the lifeline of an enterprise, and today's quality is tomorrow's market. As a newly-developed instrument lathe full-automatic pipe cutting machine by Longxin Machinery, the company has strict control over product quality.

With the continuous development of quality management, quality management has changed from the previous emphasis on results to the current emphasis on prevention. It is necessary to change the “post-mortem check” to “prevention beforehand” and change management results to management factors. Therefore, the instrument lathe full-automatic pipe cutting machine manufacturer Longxin Machinery shall start from the factors that affect the product quality in the implementation of quality management and conduct preventive management. Throughout the entire production process, there are six main factors that cause product quality fluctuations: people, machines (machines and equipment), materials (materials), methods (methods), measurements (measurements), and rings (environments). factor. Instrumentation lathe automatic pipe cutting machine manufacturer Longxin Machinery briefly introduces and explains these six factors and prevention and control measures.

Six factors that cause product quality fluctuations:

a) Person: operator's knowledge of quality, technical proficiency, physical condition, etc.; b) machine: precision and maintenance of machinery and equipment, etc.; c) material: material composition, physical properties and chemical properties; d) Method: This includes the processing technology, tooling selection, and operating procedures, etc.; e) Measurement: Whether the method taken at the time of measurement is standard or correct; f) Environment: Temperature, humidity, lighting and cleaning conditions of the work site.