English

English

Laser cutting technology has become an essential tool in many industries, including manufacturing, automotive, aerospace, and more. Its many benefits make it a popular choice for precision cutting, engraving, and marking applications. However, careful consideration must be taken when selecting a laser cutting machine, and proper training and maintenance should be prioritized to ensure optimal performance.

One of the most significant benefits of laser cutting technology is its precision. The laser beam is incredibly precise, allowing for intricate and detailed cuts with little to no room for error. This level of accuracy ensures consistent results and reduces material waste, making it a cost-effective option for many businesses.

Another advantage of laser cutting technology is its versatility. It can cut a variety of materials, including metals, plastics, and wood, with ease. This makes it a valuable tool in many industries, from jewelry making to automotive manufacturing.

In addition, laser cutting technology is faster and more efficient than traditional cutting methods. It can cut through thicker materials in a shorter amount of time, reducing production time and increasing output. This speed and efficiency also contribute to cost savings and increased profitability.

While laser cutting technology offers many benefits, careful consideration must be taken when selecting a laser cutting machine. It's essential to consider the specific needs of your business and the materials you plan to cut.

Factors such as the laser's power, the bed size, and the machine's capabilities should all be taken into account. Choosing the right machine for your business will ensure optimal performance and help you achieve your production goals.

Additionally, it's crucial to consider the machine's reliability and durability. Investing in a quality machine may require a higher upfront cost but will save you money in the long run by reducing downtime and minimizing repairs.

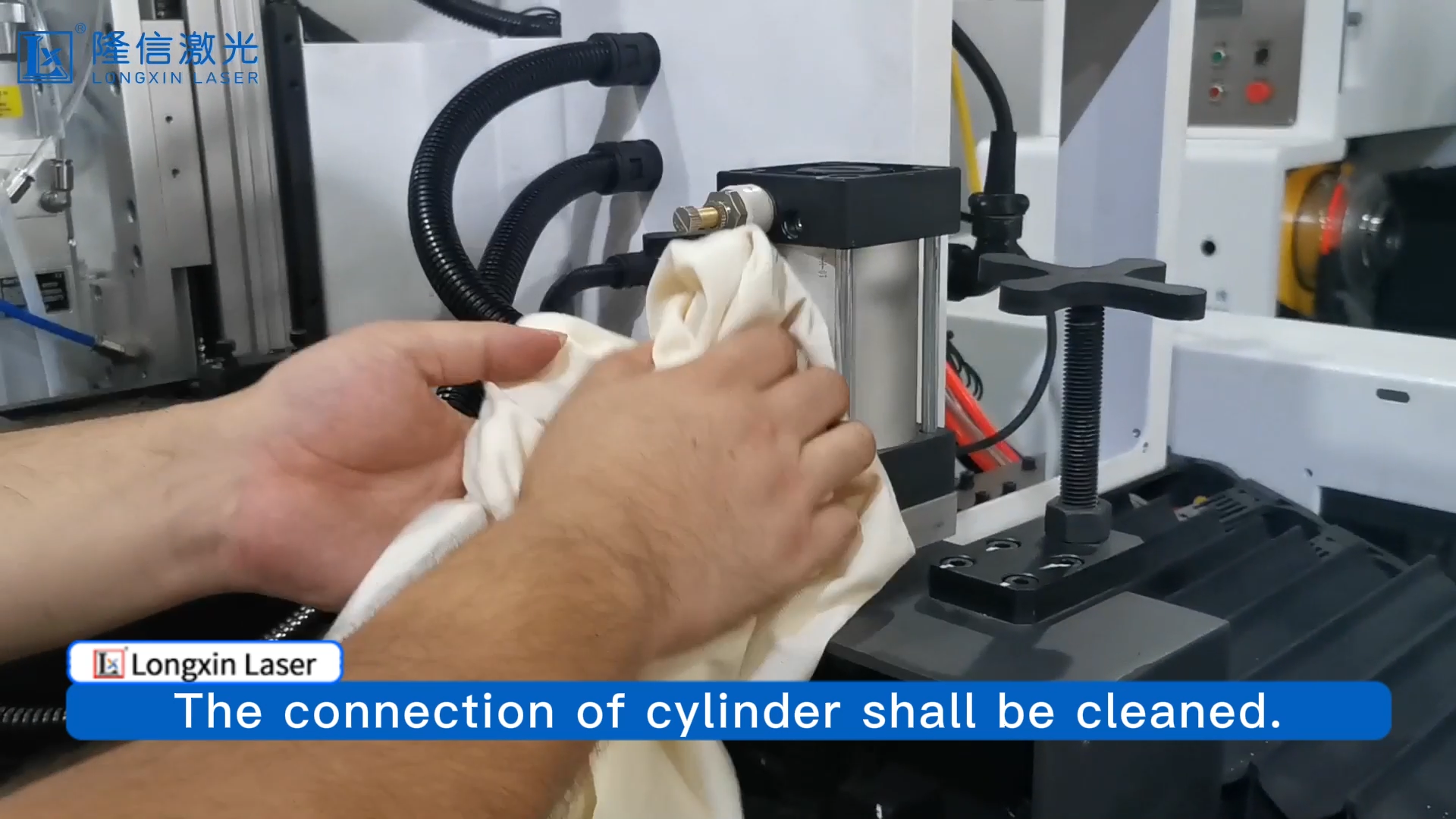

Proper training and maintenance are essential for maximizing the benefits of laser cutting technology. Operators must be trained to operate the machine safely and effectively, reducing the risk of accidents and errors. Proper maintenance, such as cleaning the machine regularly and replacing worn parts, will ensure optimal performance and extend the machine's lifespan.

Regular maintenance and upkeep will also help identify potential issues before they become more severe, reducing downtime and increasing productivity.

In conclusion, laser cutting technology offers numerous benefits, including precision, versatility, and efficiency. However, careful consideration must be taken when selecting a machine, and proper training and maintenance are crucial for optimal performance. By prioritizing these factors, businesses can maximize the benefits of laser cutting technology and increase their profitability.