English

English

Laser cutting machine has many advantages, the most important are the following:

1. Laser cutting is a non-contact process, which means that the laser beam used for laser cutting does not physically touch the material it uses, but instead causes the melting and cutting process by heating. This means that damage to the material is minimized and maintenance and maintenance schedules for moving parts in contact with the work surface can be avoided.

2. Laser cutting uses low power. This is an important advantage, because in this world, while reducing costs, increase production, rather than work harder. Laser cutting machines use only about 10 kW of electricity, and other cutting processes use more in the range of about 50 kW.

3. Laser cutting can use many different materials, whether metal, diamond, plastic, wood, glass or other materials, laser cutting is not a problem, it can be reduced in size, or help create complex and complex shapes.

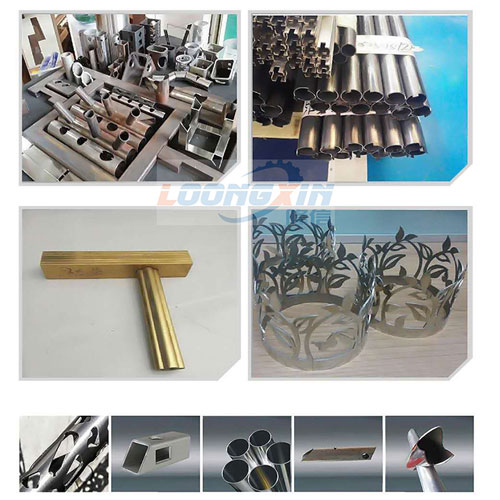

Long Xin mechanical laser cutting machine processing is suitable for stainless steel, carbon steel, alloy steel, copper, aluminum, titanium and other metal pipe hole, oblique cutting, 45-degree cutting, contact cutting, oblique cutting, hollow drilling and other processing.