English

English

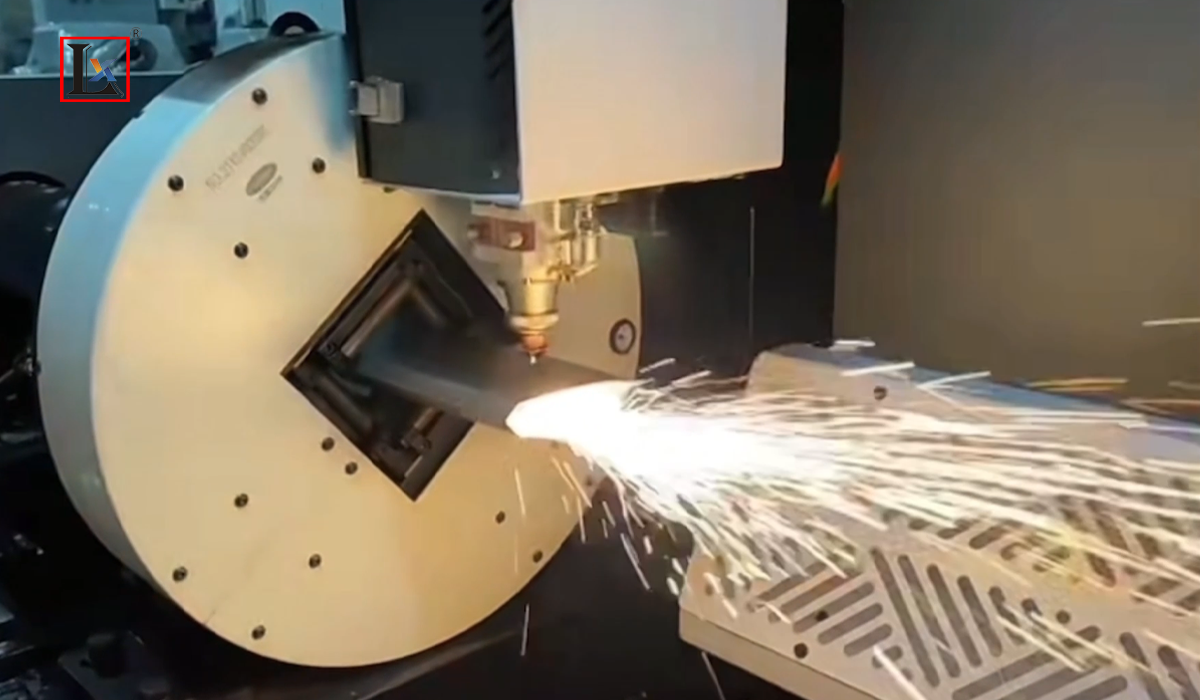

Pipe cutting includes pipe straight cutting, oblique cutting, hole opening and grooving, and processing of various intersecting line shapes at the end and the end. Saw blade cutting and laser cutting are commonly used. For the case of small cutting volume, mainly use Mechanical cutting methods, such as saw blade pipe cutting machine, turning knife pipe cutting machine, band saw cutting, grinding wheel cutting, in the face of modern manufacturing production and technology, these machines with low efficiency and large labor demand can no longer To meet the production needs, and laser cutting machine as an advanced processing tool is gradually entering the pipe cutting market.

Laser pipe cutting machine is widely used in sports equipment production, bathroom pipe fittings production, home appliance manufacturing industry, household product manufacturing and other industries. The processing objects include carbon steel pipe, silicon steel pipe, stainless steel pipe, aluminum alloy pipe, titanium alloy pipe, galvanized pipe , copper pipes, etc.;

1.The incision is smooth and beautiful, and there are no burrs, no deformation, and no oxidation inside and outside the incision, which can cut out higher quality and more consistent pipe fittings, which is beneficial to the processing of the next process;

2. The cutting precision is high, and the precision of the pipe cut by Longxin laser pipe cutting machine can reach 0.05mm.

3. The cutting efficiency is high, and mass production can be realized; all operations of the laser pipe cutting machine can be unified into the same unit as a continuous operation process, reducing the flow time of materials between various processes, and the automatic feeding laser of Longxin Laser The pipe cutting machine can also automatically load and continuously feed materials, which further improves the production consultation of batch pipe cutting machines.

4. The laser pipe cutting machine is controlled by a digital system, which is also one of the advantages of the laser pipe cutting machine. Using this system, the laser pipe cutting technology can process any shape that has been programmed, and it is also in the cutting process. The design scheme can be modified without affecting the entire product production process.

Products processed by laser tube cutting machines have more advantages than the old traditional cutting in terms of technology and quality. Friends who need to know professional laser tube cutting machines come to consult Longxin Laser!