English

English

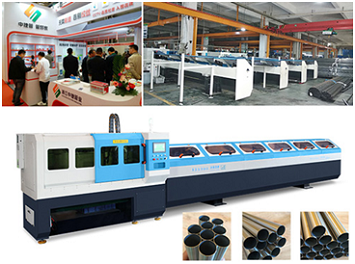

With the continuous development and improvement of the laser industry, the laser pipe cutting machine has become a new field of tube cutting breakthrough in recent years. With the demand for pipe forming at home and abroad, laser cutting machine has gradually become the best choice for many industries such as fitness equipment, lighting, decoration, furniture, kitchen and bathroom, etc. The traditional processing methods like the plasma gun cutting, abrasive stamping, and drilling machine processing, which are with many disadvantages: complicated usage, difficult positioning, low processing precision, poor processing quality, and require many manpower. Laser cutting machine can avoid these.

1. Fitness equipment

In the process of manufacturing fitness equipment, various of pipes cutting is required. With the innovation and upgrading of the fitness equipment industry, the requirements for processing technology are getting higher and higher, and the laser cutting machine brings a new processing technology for them due to it can cut high-speed quality of round pipe, square pipe, rectangular pipe and special-shaped pipe, and make holes and cutting at the same time. Without opening the mold, laser pipe cutting machine can greatly saves the development time of new products.

2. Furniture

Due to the difficulty of metal processing, the price of metal furniture in the past was very expensive. Compared with the traditional processing method, the laser cutting machine has the advantages of arbitrary adjustment of size, high precision, high speed, smooth cut without burr, and no mold consumption.

3. Decoration

Metal decoration materials have strong luster and color, fire resistance and durability. They are widely used in interior and exterior wall, cylinder, door frame and other parts decoration. The flexibility and high precision of the laser cutting machine is great choice for cutting copper, aluminum, stainless steel materials.

4. Bathroom

Since the stainless steel material itself is not easy to oxidize, corrosion-resistant, not afraid of collision, high quality and smoothness, etc., the development trend of kitchen equipment and bathroom facilities is the increase demands on stainless steel products. Laser processing allows a piece of stainless steel to become a variety of stainless steel kitchen accessories and cabinets in a matter of seconds.