English

English

Embracing the laser advantage for small pipe solutions unlocks a range of benefits and possibilities. Here's why laser technology is particularly advantageous for cutting small pipes:

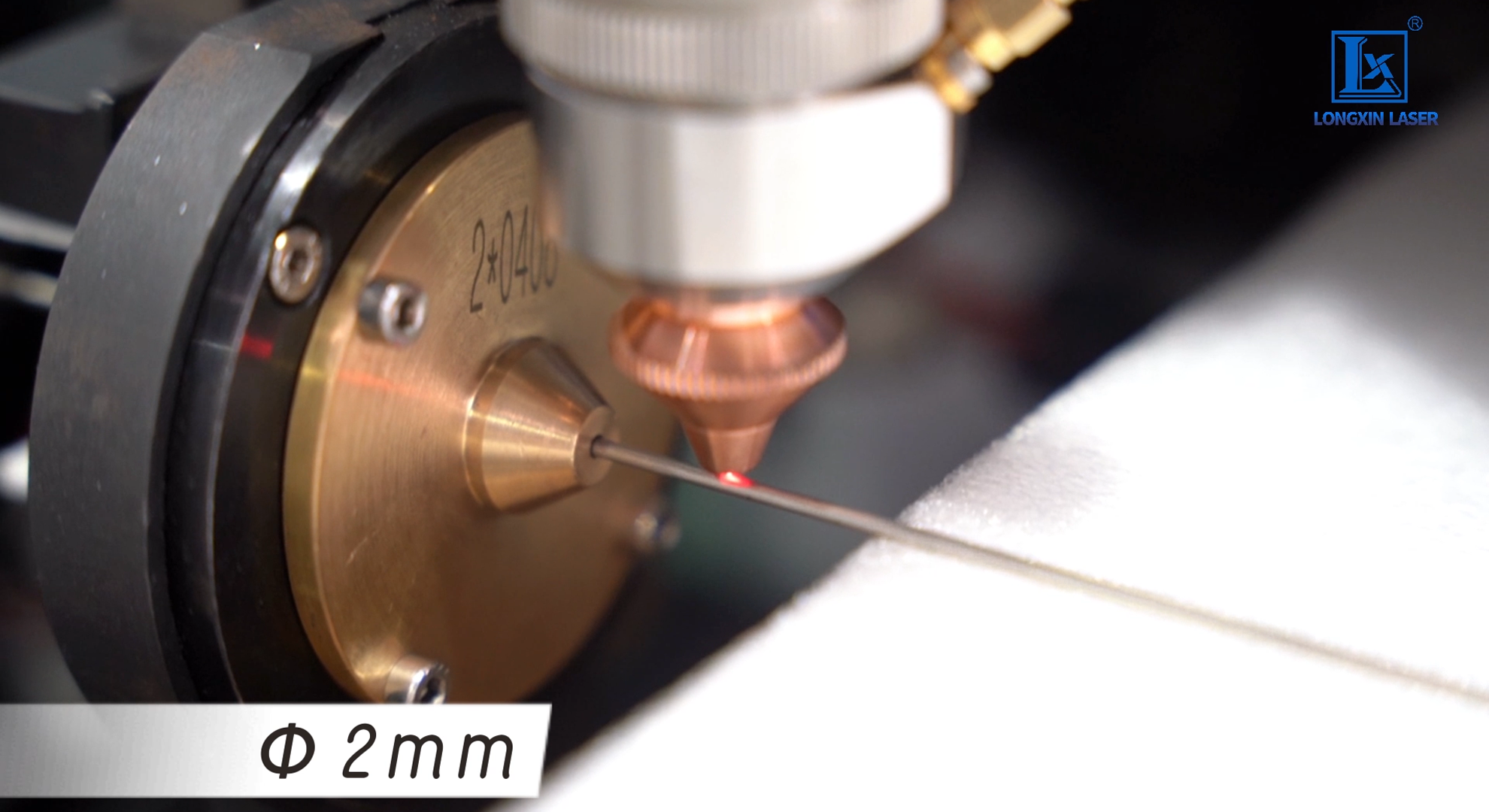

Precision and Accuracy: Laser pipe cutting machines offer exceptional precision, allowing for precise and accurate cuts even on small pipes. The focused laser beam can achieve narrow kerf widths, enabling intricate designs, sharp corners, and fine details. This precision ensures tight tolerances and high-quality finished products.

Versatility in Small Pipe Sizes: Laser pipe cutting machines can handle a wide range of small pipe sizes, including diameters as small as a few millimeters. Whether it's thin-walled tubes or small-diameter pipes, laser technology provides the flexibility to cut these smaller dimensions with precision, regardless of the material.

Non-contact Cutting: Laser pipe cutting is a non-contact process, meaning the laser beam does not physically touch the pipe during cutting. This non-contact nature eliminates the risk of deformation, distortion, or damage to small pipes, which can be more susceptible to bending or warping under the pressure of traditional cutting methods.

Minimized Heat-Affected Zone (HAZ): Laser pipe cutting generates a minimal heat-affected zone, especially when compared to other cutting methods like plasma or flame cutting. This reduced HAZ is particularly important for small pipes, as it helps preserve the structural integrity and dimensional accuracy of the cut pieces, minimizing the need for additional post-processing or rework.

Small Material Waste: Laser pipe cutting machines optimize material utilization, which is crucial for small pipes where efficient use of material is paramount. Advanced nesting algorithms intelligently arrange pipe designs on the stock material, minimizing waste and maximizing the number of parts cut from each tube. This translates into cost savings and increased efficiency.

Complex Geometries: Laser pipe cutting allows for the creation of complex geometries even on small pipes. Whether it's intricate patterns, slots, or bevels, laser technology can precisely cut these features on small-diameter pipes with high repeatability. This opens up possibilities for innovative designs and customized solutions.

Automation and Integration: Laser pipe cutting machines can be integrated into automated production lines, offering increased efficiency and productivity for small pipe cutting operations. Integration with robotic systems, material handling equipment, and CAD/CAM software allows for seamless workflow automation and reduced manual intervention.

Diverse Industry Applications: Laser technology for small pipe cutting finds applications in various industries. From medical devices and electronics to jewelry and small-scale manufacturing, the precision and versatility of laser pipe cutting make it suitable for producing intricate components in a range of sectors.

By leveraging the laser advantage, manufacturers can unlock the full potential of small pipe solutions. Laser pipe cutting technology provides unmatched precision, versatility, and efficiency, enabling manufacturers to achieve high-quality cuts, intricate designs, and cost-effective production processes for small-diameter pipes.