English

English

Scientists at the University of Toronto have developed a way to use an amazingly simple substance, cooking oil, to make it difficult for microbes to enter these scratches on stainless steel surfaces cut by automatic pipe cutters.

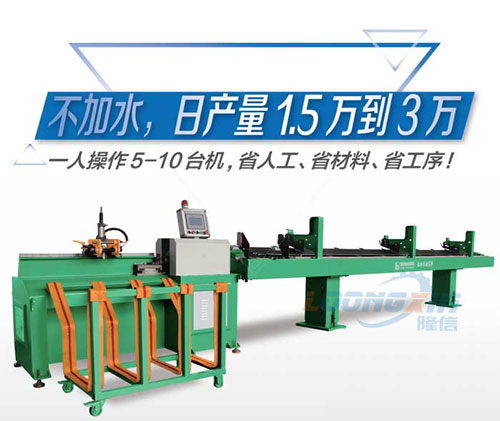

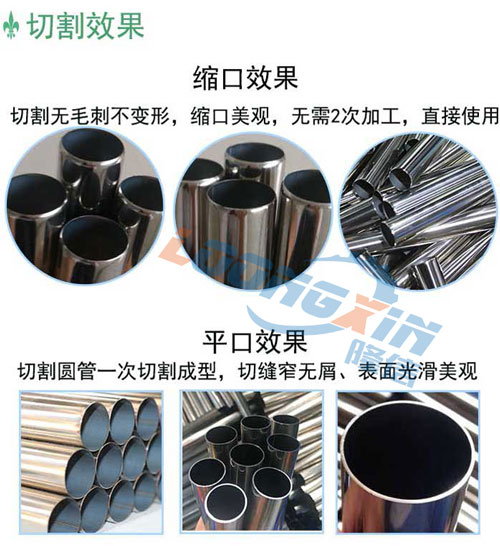

Researchers have been working on ways to treat steel surfaces in food processing machines to prevent pathogenic bacteria from settling on them and forming biofilms. They found that when these surfaces were chemically treated with alkyl phosphonic acid and then coated with a layer of food oil, the oil filled all the tiny corners and crevices, making it difficult for bacteria to enter. When tested on the internal surface of stainless steel food processing machines cut by automatic tube cutting machines, the result was a 1000 fold reduction in the bacterial level of Pseudomonas aeruginosa in these devices. Even when most reservoirs are removed, the antibacterial effect is still present, indicating that the oil remains in the scratch. Although disinfectants are commonly used to kill bacteria in such machines, nontoxic cooking oils are safe for humans and bacteria cannot tolerate them. "coated with daily cooking oil on stainless steel surfaces cut by automatic pipe cutting machines has proven to be very effective in removing bacteria," said ben hatton, who led the study. "the oil fills the cracks, forms a hydrophobic layer, and acts as a barrier to contaminants on the surface." Dr darel asker and Dr tarek awad were also involved in the study.