English

English

We received an inquiry from Mexico Company J in the end of 2020. Company J is a global leader in mobility safety providing safety-critical components, systems and technology to automotive and non-automotive markets.

During several times of communications by mails, Company J has grown great interest in turning to laser technology in their future business.

But it was not Company J that will use our laser tube cutting machines in the factory.

Company A is one of sub suppliers of Company J in metal fittings.

Company J will ask Company A to change the manufacture of their metal fittings by using our laser machines.

Company A is also a famous supplier of different automotive parts in Mexico with over 15 years experience.

Their factory is located in San Buenaventura, covering over 15000 square meters area with a crew of more than 100 men.

Since they have been using traditional cutting machine for metal fittings production for years, they have their doubts on turning to laser technology at the beginning.

Although it’s a direct order of using laser from their parent company, we still take some time to make several turns of technical Q&A patiently.

In the end, the management of Company A realized the purpose of their parent company, and believe that it has great potential of keeping them a leading position in automotive parts industry by using our laser tube cutting machines.

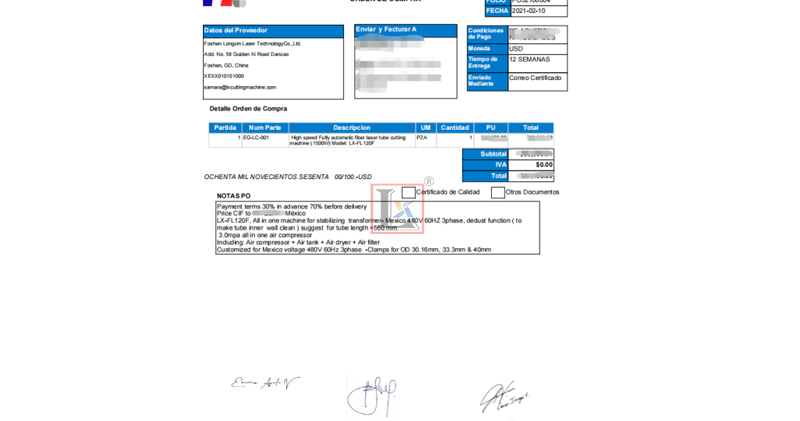

They placed their first order of FL120F at the beginning of last February.

Their first FL120F was successfully made in the middle of 2021.

Here are the testing videos of the machine we made at that time:

Cutting 32x2mm MS pipes with anti-spatter function:

We also make a video of packing and loading for confirmation:

Company A finally finished the custom clearance issue at the port and received the machines in their factory in November, 2021.

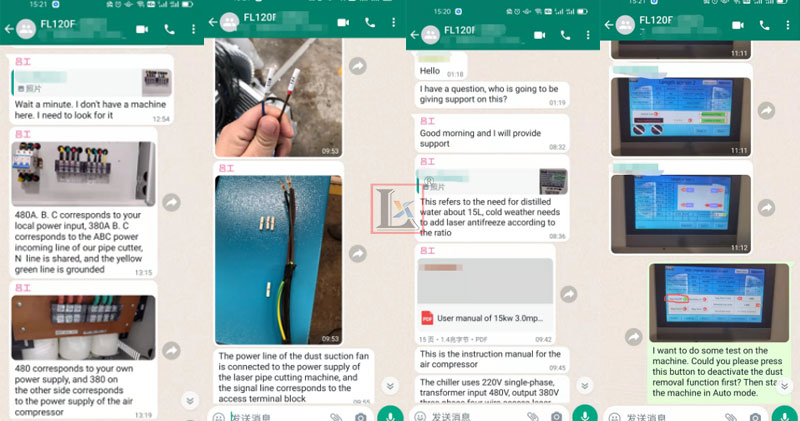

We provide our on-time technical service to them as soon as the machine was unloaded in their workshop.

We helped them finish installation and commissioning right before their Christmas holiday.

Now the machine has been in normal operation in their factory:

Under the patient & professional guidance of our technical engineers, their worker has got the hanging of the machine soon, even though they had less experience in handling CNC type machines.

This also proved that LX-Laser’s machine development is definitely based on the Humanistic Design Idea, making it easier for any operators to use modern laser machines.