English

English

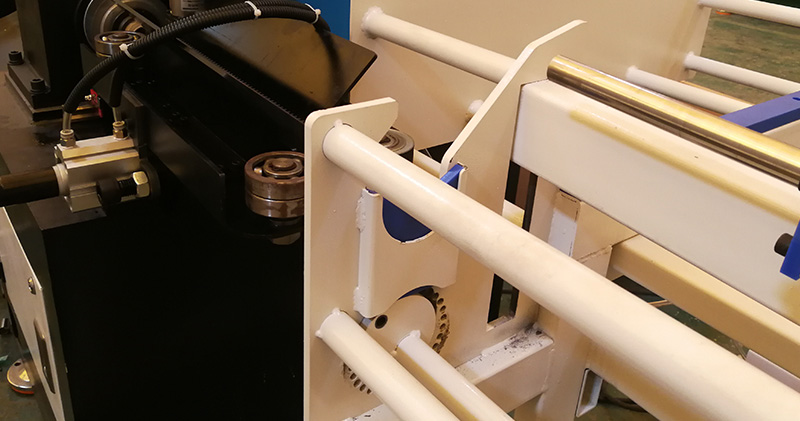

Fully Automatic CHS Tube laser cutting machine

Laser pipe cutting is a cost-effective process that produces intricate parts with small tolerances in medium to high volume production runs. It is also a fast and low-cost process for prototypes or one-off parts due to the quality of the cut and the lack of finishing operations needed.

Longxin Laser Technology's Fully Automatic CHS Tube laser cutting machine especially suitable for Φ15~40MM ROUND TUBES & those only require for cut off function, such as tube mills, metal processing plants, etc.

Longxin Laser Technology's Fully Automatic CHS Tube laser cutting machine Benefits

1.Specially for round pipe cutting:

For round pipe cutting:φ15-φ40mm with cutting length 10mm-1200mm

2.High speed cutting:

For long cutting length less cutting time.

Fully automatic cutting machine can reach 0.3sec/cut for φ19 × T0.3 × L500mm. Faster than the semi automatic three times.

3.High stability, easy operation:

It’s easy to change the pipe clamps for its simple structure to ensure high stability and easy operation.

4. Automatic feeding, saving material and labor cost and improving efficiency

Automatic cutting products conveying. Easy operation design, one man can operate 5-10 machines at the same time.

5.Automatic sensing and cutting the pipe heads

Photo-sensing pipe heads . Save labor handling procedure.

Semi-Automatic Laser Tube Cutting Machine

Main Techincal Parameters

| Model | LX-FL40F |

| Power of fiber laser | 500-2000W(optional) |

| Tube size range | Round tube Φ15~40MM |

| Tube thickness | ≤1.5mm (depends on the material) |

| Machine Dimension | 9455*1332*1598mm |

| Cutting speed | Max 0.8s/ cut(depends on the thickness) |

| Max. Cutting Length | 1200MM( could be customized) |

| PLC | Mitsubishi Japan |

| Accuracy | ±0.1MM |

Cutting Speed of Laser ( Stainless Steel Tube, 800W )

| Thickness ( MM ) | Laser Speed ( M/MIN ) |

| 1 | 13~14 |

| 2 | 2.6~2.9 |

| 3 | 0.9~1.1 |

| 4 | 0.5~0.6 |

Cutting Speed of Laser ( Carbon Steel Tube, 800W )

| Thickness ( MM ) | Laser Speed ( M/MIN ) |

| 1 | 15~16 |

| 2 | 3.5~4.5 |

| 3 | 2.0~2.2 |

| 4 | 1.5~1.6 |

| 5 | 0.9~1.1 |

| 6 | 0.6~0.7 |

Longxin Laser Technology has the capabilities to provide prototype machines to our customers at a competitive price with short lead times. We can work from samples, rough sketches, or finished engineering drawings. We can also provide Free Tube Sample Cutting. We will also fabricate parts per print when possible or supply a marked up copy of any necessary changes for customer approval prior to production.

Quality Control Standards

To ensure the best quality products possible we provide pressure testing of all finished parts and assemblies created by our 4 axis laser cutting system. Every product that leaves our facility is thoroughly inspected at all stages of production to the industry's highest standards for quality. At Longxin Laser Technology, we strive to meet or exceed customer requirements and expectations through a continued dedication to customer service, quality and productivity.

After-sales Service

Our company also provides free technical training. After the installation and commissioning, we will carry out technical training for the buyer's operators for at least 3-5 days at the buyer's site or at the seller's domestic training and repair center until the operators reach the basic normal use of the equipment.

Furthermore, We offer 1 year warranty, starts from the issue date of bill of lading. The warranty time for laser generator, laser head is 24 months. And we offer lifetime technical supports. After the expiration of the warranty, extensive software and hardware support is provided, and free upgrades are available for life.

Our engineers offer 24 hours online service and free technical support. We are a professional pipe processing equipment manufacturer with 16 years experience. We have professional R&D department and after-sales department to offer you the best solution and technical support.