English

English

Client Background:

Our client operates in the baby stroller accessories industry, specializing in the production of waist-shaped tubes. They sought an innovative solution to enhance their production efficiency and reduce material waste. After thorough research, they invested in our LX-K9 High-Speed Short Waste Material Laser Tube Cutting Machine.

Challenge:

The client faced challenges in efficiently cutting waist-shaped tubes while minimizing material waste. Traditional cutting methods were time-consuming and resulted in significant material loss, leading to increased production costs.

Solution:

Our LX-K9 High-Speed Short Waste Material Laser Tube Cutting Machine proved to be the perfect solution for our client's needs. Equipped with advanced laser cutting technology and a specialized design, this machine ensures precise cutting of waist-shaped tubes while minimizing waste.

Results:

Upon integrating the LX-K9 into their production process, our client experienced remarkable improvements:

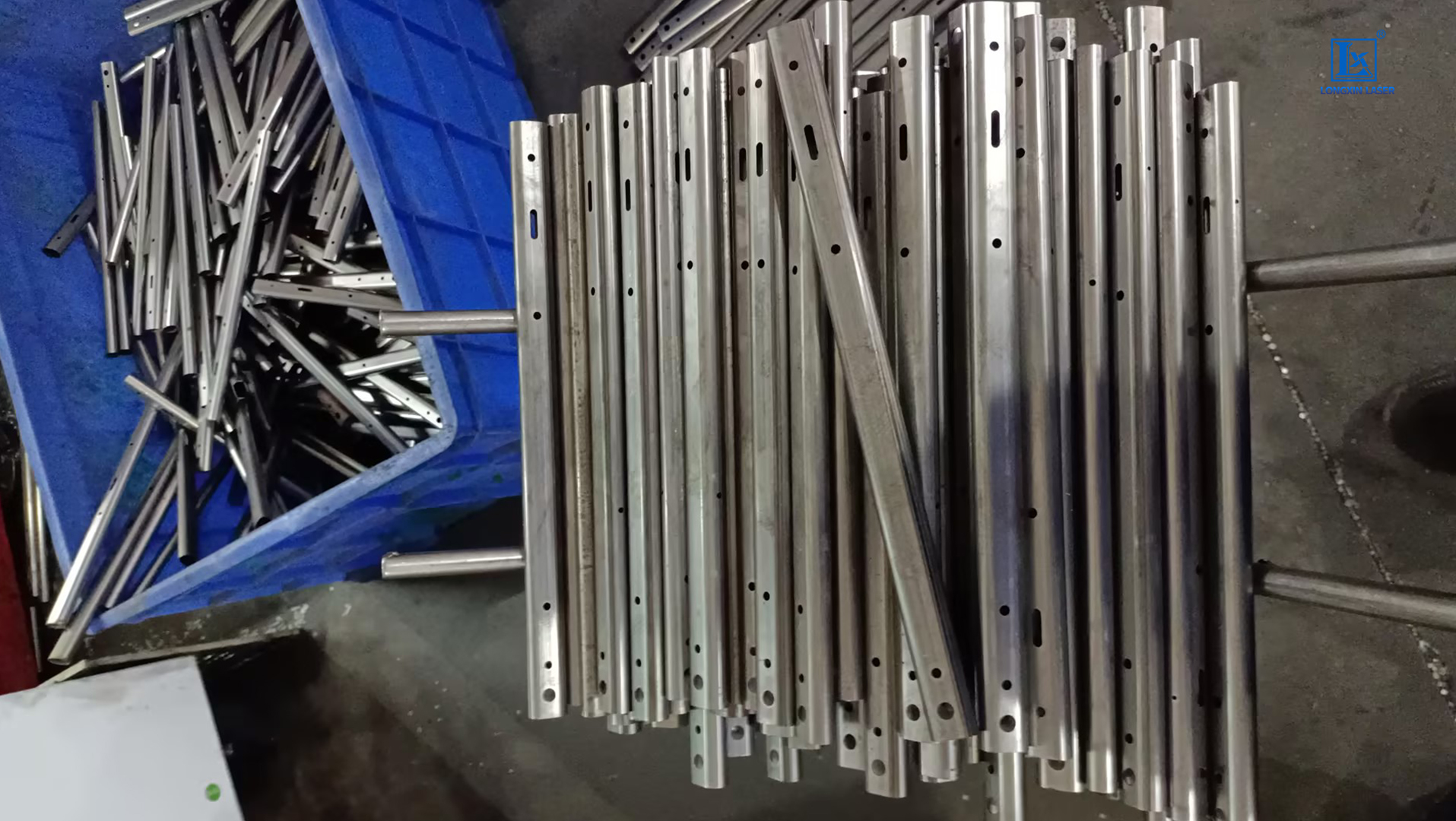

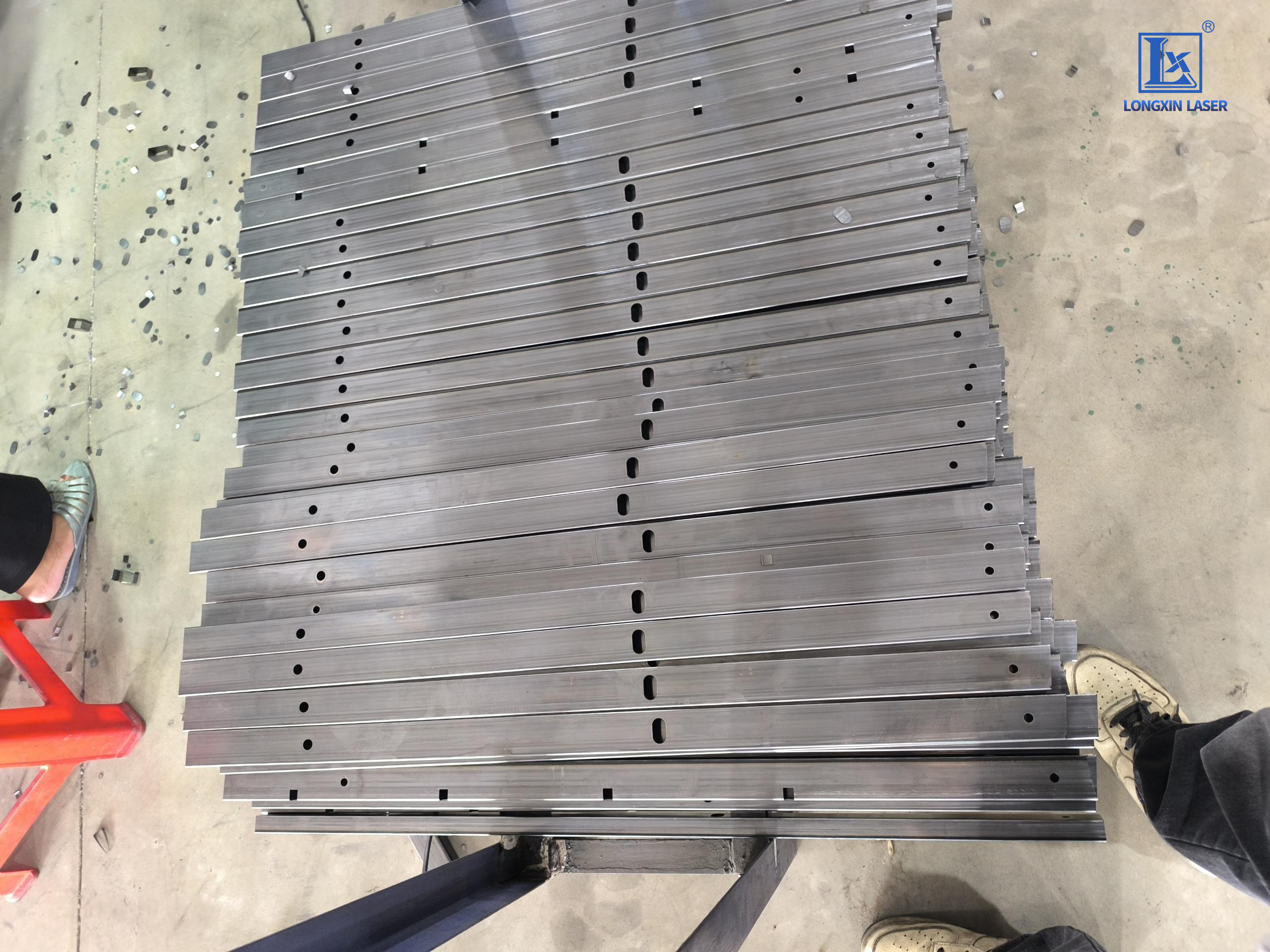

Material Savings: The LX-K9's high-speed cutting and intelligent design allow for the precise cutting of waist-shaped tubes, significantly reducing material waste. With the laser head able to move to the rear of the chuck for cutting, material waste was reduced to a minimum, resulting in substantial cost savings.

Enhanced Production Efficiency: The LX-K9's high-speed cutting capabilities enabled our client to complete the cutting process at a much faster rate compared to traditional methods. This increased production efficiency, allowing them to meet customer demands more quickly and effectively.

Improved Product Quality: The LX-K9's advanced laser cutting technology ensures accurate and consistent cuts, resulting in high-quality waist-shaped tubes. This enhanced product quality has boosted customer satisfaction and garnered positive feedback.

Competitive Advantage: By implementing the LX-K9 into their production line, our client gained a significant competitive edge in the baby stroller accessories industry. With improved efficiency, reduced material waste, and enhanced product quality, they can offer their customers superior products at competitive prices.

Conclusion:

Through the integration of our LX-K9 High-Speed Short Waste Material Laser Tube Cutting Machine, our client in the baby stroller accessories industry achieved remarkable results. They experienced increased production efficiency, significant material savings, and improved product quality. These advantages have positioned them as a leader in their industry, allowing them to meet customer demands effectively and stay ahead of the competition.