English

English

Longxin Laser Precision Small Tube Laser Cutting Machine: Advancing Ultrasonic Scalpel Manufacturing in the Medical Industry

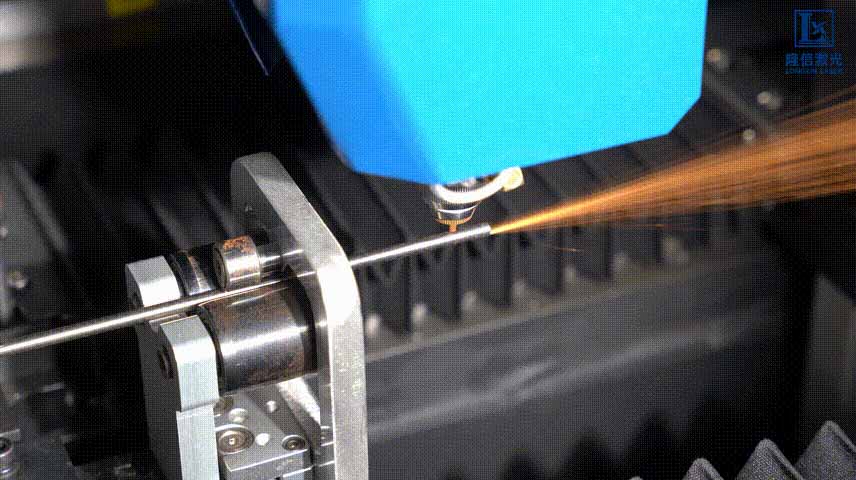

In the field of medical device manufacturing, precision machining technology plays a decisive role in product quality and performance. The ultrasonic scalpel, a critical tool in minimally invasive surgery, relies heavily on the cutting quality of its core component—precision steel tubes—which directly affects the instrument's accuracy and reliability. Leveraging years of expertise in laser cutting technology, Longxin Laser has introduced a precision laser tube cutting machine specifically designed for the medical industry, providing efficient and accurate cutting solutions for ultrasonic scalpels and surgical blades.

Industry Challenges: The Difficulties of Precision Tube Cutting for Ultrasonic Scalpels

The core components of ultrasonic scalpels are typically made of high-precision stainless steel or titanium alloy tubes, demanding extremely stringent cutting quality:

High Precision Requirements: Cuts must be exceptionally accurate to ensure assembly precision.

Burr-Free and No Thermal Damage: Traditional cutting methods often produce burrs or thermal deformation, compromising safety and lifespan.

Complex Shape Machining: Some ultrasonic scalpels require special-shaped cuts or micro-hole drilling, which conventional techniques struggle to achieve.

Facing these challenges, traditional mechanical cutting or waterjet cutting can no longer meet industry demands. In contrast, laser cutting technology, with its non-contact operation, high precision, and flexibility, has become the preferred solution for medical precision tube processing.

Core Advantages of Longxin Laser’s Precision Small Tube Laser Cutting Machine

Longxin Laser’s newly developed precision laser tube cutting machine is optimized for ultra-fine and ultra-thin medical-grade tubes, offering the following technological highlights:

Ultra-High Precision Cutting – Repeat positioning accuracy of ±0.03mm/m

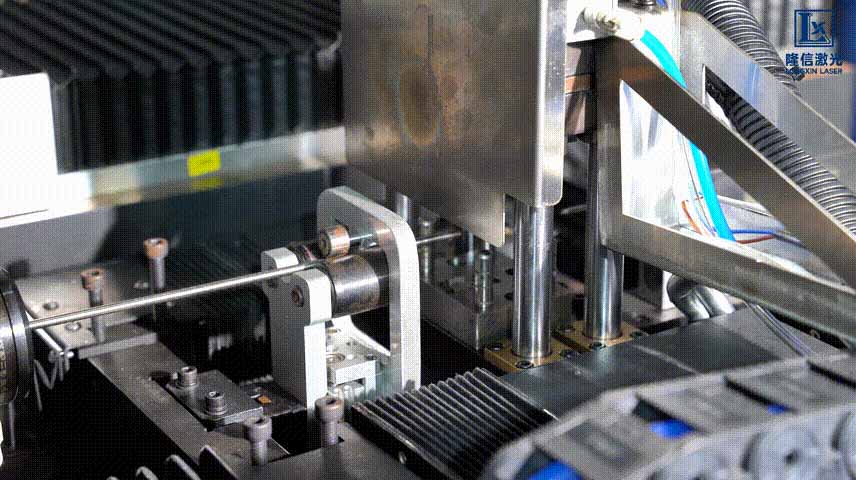

Equipped with linear motors, high-precision servo control systems, and industry-leading lasers, ensuring dimensional stability to meet stringent medical-grade requirements.

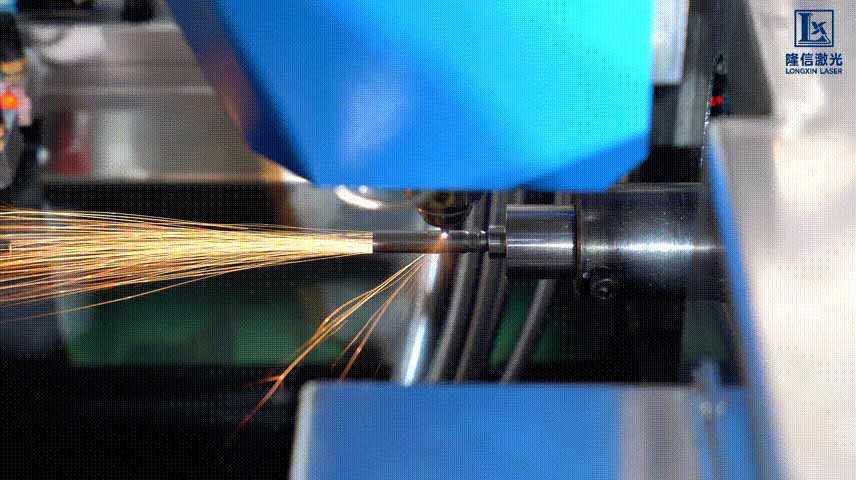

Burr-Free and No Thermal Deformation

Optimized laser parameters and auxiliary gas control enable cold cutting effects, producing smooth, burr-free edges and eliminating the need for secondary processing.

Capable of Ultra-Fine Tube Cutting

Designed for ultra-thin steel and titanium tubes commonly used in ultrasonic scalpels, the machine features high-stability clamps and a precision rotation system to prevent deformation.

Smart Programming for Complex Shaped Cuts

Capable of bevel cuts, slotting, micro-hole drilling, and other complex shapes to accommodate various ultrasonic scalpel designs.

Integrated with an intelligent tube cutting system, including auto-edge detection, auto-centering, automated feeding, and in-process inspection, significantly improving efficiency.

Clean and Eco-Friendly, Compliant with Medical Standards

Laser cutting is contamination-free, ensuring a clean production environment that complies with medical industry regulations.

Customer Case Study

An internationally renowned medical device manufacturer achieved the following after adopting Longxin’s precision small tube laser cutting machine:

✅ 30% increase in yield rate, reducing post-processing steps like deburring and polishing.

✅ 50% improvement in cutting efficiency, enabling automated mass production.

✅ Single-step complex shape cutting, shortening product development cycles.

Longxin Laser is committed to providing innovative laser solutions for high-end manufacturing. Our precision laser tube cutting machine offers robust support for the localization of high-end medical devices like ultrasonic scalpels.

If you’re seeking a high-precision, high-efficiency medical tube cutting solution, contact Longxin Laser today—let us help you achieve a technological upgrade!