English

English

First contact on April 4th, 2019

Industry: Furniture - Chairs

Previous cutting by band saw & circular saw

Requirement: want machine to increase the production capacity and reduce the labor cost

Pipe information:

| Material | Carbon steel & Stainless steel |

| Diameter | 12-25mm |

| Thickness | Maximum 1.5mm |

| Cutting length | 20-1200mm |

Machine purchased: 3 sets 500W laser tube cutting machines, includes:

2 sets of LX-FL40

Semi-automatic laser tube cutting machine

1 set of LX-FL40F

Fully automatic laser tube cutting machine

Before purchase, customer has below questions:

1.Does the cutting time different from carbon steel pipes and stainless steel pipes?

- The cutting time for both material is similar for thickness 1.5mm by using compressed air for cutting.

2.What air pressure should be set on the compressor?

- We have a guide sheet for our customer to show the air pressure for cutting on different tube thickness. Such as cutting 1.5mm thickness carbon steel tubes, suggest to use 14-16kg (203-232psi)

3.Is it possible to get different length on one pipe?

- Yes, our machine can do different cut length on one pipe, just do the setting on touch screen.

4.How many servo motors in our machine?

- LX-FL40: 3 servos, cutting length + cutting head + pipe rotation.

- LX-FL40F: 4 servos, pipe feeding + cutting length + cutting head + pipe rotation.

Machine test before shipment

Machines in customer's factory

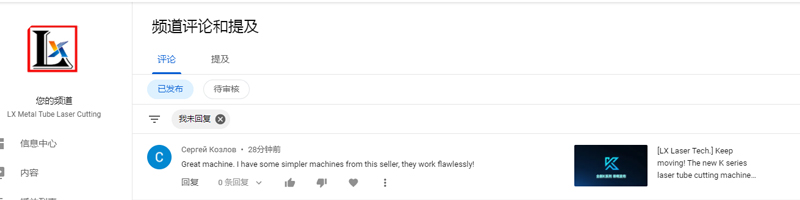

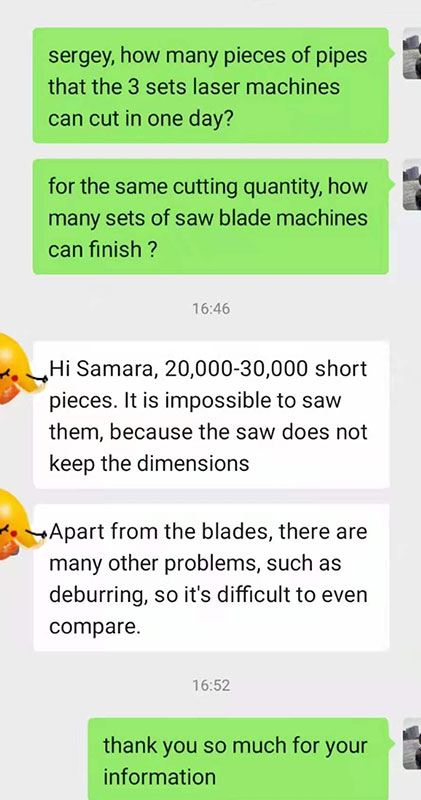

According to customer’s feedback, our machines cuts 20,000-30,000pcs per day that the saw cutting machine can never reach this capacity. They even gave good comment on our YouTube channel. :)

Customer feedback

Comment on YouTube