An Expert in Stainless steel

Pipe making machine / tube mill, Since 2003

Production speed up to 25 m/min,

high precision and quality – LX decorative tube mill series

Suitable for round pipes, square pipes and rectangle pipes, customized shaped-pipes etc.

- Applicable materials: stainless steel, carbon steel, galvanized iron, mild steel, copper and aluminum etc.

- Application:

- Furniture industry: Steel table tubes, Steel chair tubes, Steel bed tubes, Steel towel racks, etc.

- Construction industry: Steel guardrail, steel door, steel handrail and steel window, etc.

- Public facility industry: Flagpoles, outdoor sports equipment, bus and metro handrails, etc.

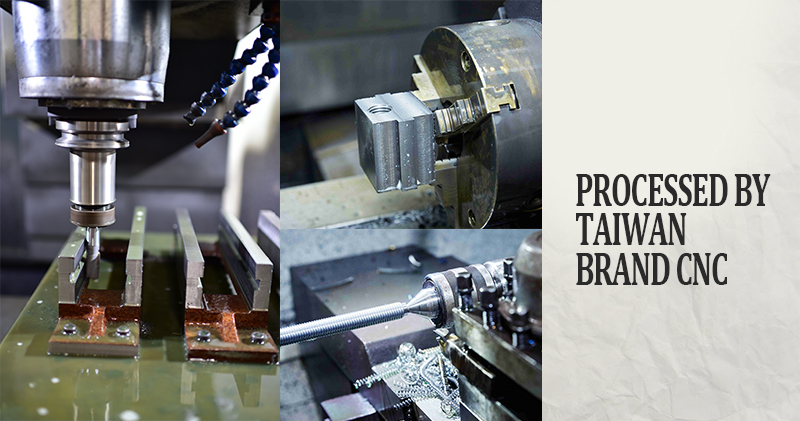

All mechanical parts are processed by

Taiwan brand CNC in order to keep all mechanical parts standardized and uniform

- Easier and faster to obtain original parts for replacing broken parts once occurred during production

- Ensure high precision,more stability and more durable

Adopt famous electric components to ensure running stability

- Siemens frequency motor, Schneider contactor, Toshiba converter

- grinding motor adopt famous Chinese Jiangcheng brand more durable

Adopt Q235B material steel plate from BaoSteel, which is within Top 5 all over this world

- Ensure more stable by raw material choose, avoid deform

- Greatly improve durable and long service time

Adopt Ultrasonic welding machine instead of common TIG welding machine

- more save argon gas than 30%,

- welding more penetration, welding speed faster

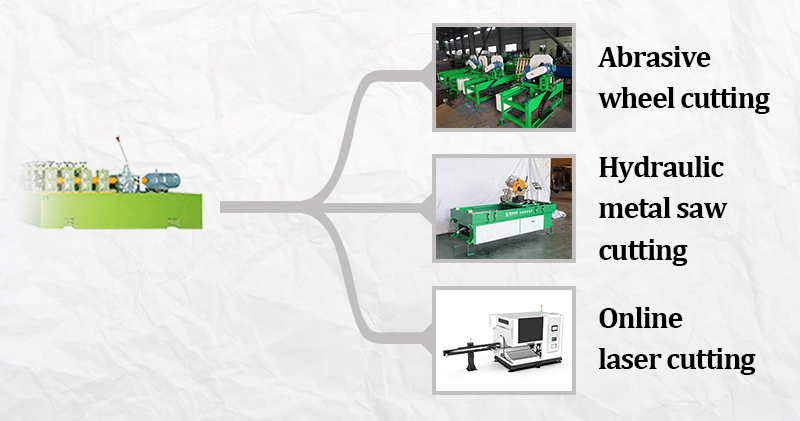

Innovation design

for cutting stage

from LX Laser cutting

Use laser cutting machine and technology

instead of hydraulic metal saw cutting

and abrasive wheel cutting

Advantages:

- LX Laser combines the fruitful experiences in the "inline HSS saw cutter" and the fiber laser technology, launch the unique and brand new "Laser Inline Synchronous Cutting Machine"

- Exact cutting precision

- Waste lowest materials, laser cutting gap 0.1mm, HSS saw blade cutting gap around 3mm, Abrasive cutting gap around 5mm

- No burr after laser cutting, HSS saw blade cutting and abrasive cutting both need cleaning burr further and waste labor, increasing production cost

- Cut any length what clients want

- Laser cutting improve working environments.

| Model No. | ZG-S40 | ZG-40 |

| Pipe Range(mm) | Φ6-Φ25.4 | Φ12.7-Φ50.8 |

| wall thickness(mm) | 0.2-1.2 | 0.2-2.0 |

| Motor Power | 4KW*2 | 5.5KW*2 |

| Speed of Pipe/Tube | 5-25m/min | 5-25m/min |

| Horizontal shaft | 40 | 40 |

| Vertical shaft | 25 | 25 |

| Model No. | ZG-B40 | ZG-50 |

| Pipe Range(mm) | Φ12.7-Φ63.5 | Φ25.4-Φ76.2 |

| wall thickness(mm) | 0.2-2.0 | Φ40 |

| Motor Power | 7.5KW*2 | 7.5KW+11KW |

| Speed of Pipe/Tube | 5-25m/min | 5-15m/min |

| Horizontal shaft | 40 | 50 |

| Vertical shaft | 25 | 30 |

| Model No. | ZG-60 | ZG-70 |

| Pipe Range(mm) | Φ63.5-Φ114 | Φ101.6-Φ168 |

| wall thickness(mm) | 0.4-3.0 | 0.5-4.0 |

| Motor Power | 11KW+15KW | 18.5KW*2 |

| Speed of Pipe/Tube | 5-10m/min | 1-10m/min |

| Horizontal shaft | 60 | 70 |

| Vertical shaft | 40 | 50 |

| Model No. | ZG-90 |

| Pipe Range(mm) | Φ168-Φ219 |

| wall thickness(mm) | 0.6-5.0 |

| Motor Power | 22KW*2 |

| Speed of Pipe/Tube | 1-10m/min |

| Horizontal shaft | 90 |

| Vertical shaft | 60 |

1. What service you can provide?

- We are a professional manufacturer since 2003 in China, and provide you direct factory price.

- Additional, our factory has professional R&D team and after-sales service team to installation and debugging, guide your workers how to make pipes well.

- Depend on raw material character, for example, Jindal 201 and 304, we will offer customized roll sets to solve scratch line and needle dot, to making perfect tubes and pipes.

- For new plant, we will provide wholly sketch, design and guidance.

- For production issue, we can provide best technical solution and online video for guidance.

- Provide reasonable investment suggestion and approximate investment cost, provide investment feasible report, and offer suitable machine model to clients.

- Free for providing plant equipment drawings.

- Free for providing installation layout.

- Providing machine's installation and debugging, training and selling information.

2. For decorative pipes, what production per day by one tube mill with 10 hours?

By statistics, it is approximately 1.3T by 1 tube mill with 10hours (one shift)

3. In addition to stainless steel pipes, can your machine make pipes of other materials?

Our machine can make carbon steel pipes, mild steel pipes, galvanized steel pipes, aluminum pipes, copper pipes, titanium alloy pipes in addition to stainless steel pipes.

4. What lead time if we want to order from you?

Normally lead time is within 40 days, it is depend on orders' quantity.

5. How to get the technical support?

First, we will arrange our skilled engineers for installation, debugging and training, also we will provide online technical support by videos. Second, our engineer will visit clients by regular period

6. How many year for your machine guarantee?

1 year for wholly machine, 3 months for electrical parts, we will provide for free replacement during transportation, installation and commissioning.