English

English

How to cut square tube ?

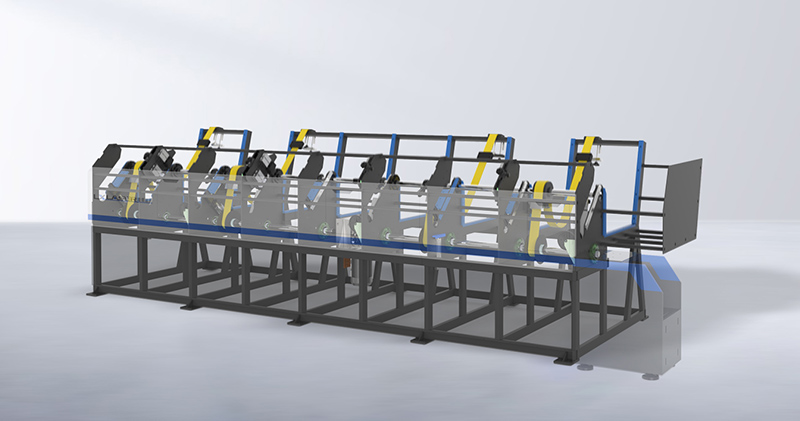

Ultra-rapid speed cutting, specially designed for furniture industry – LX-K6

Ultra-rapid speed laser cutting, short tail material

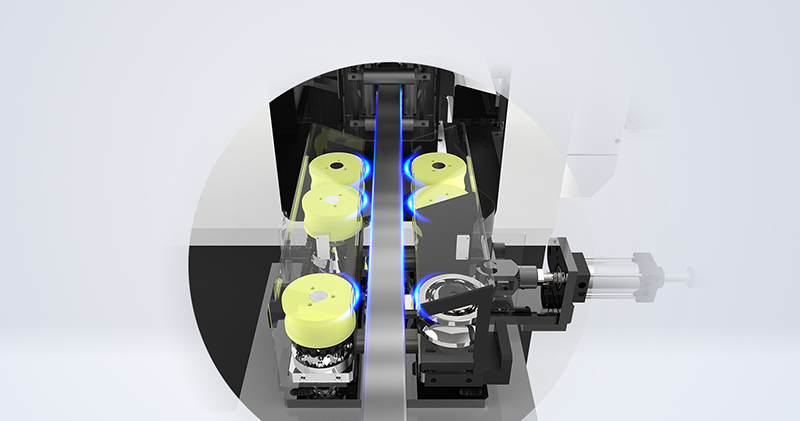

- Compared with universal laser tube cutting machines, the cutting speed is 30% faster!

- Machine acceleration up to 1.5G!

- The minimum tail material length can be just 40mm!

Fully automatic bundle loading

- Skip production processes and minimize the labor costs and consumables

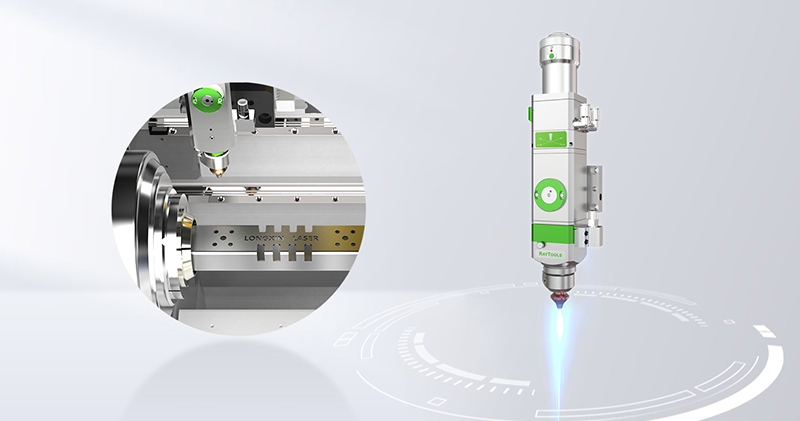

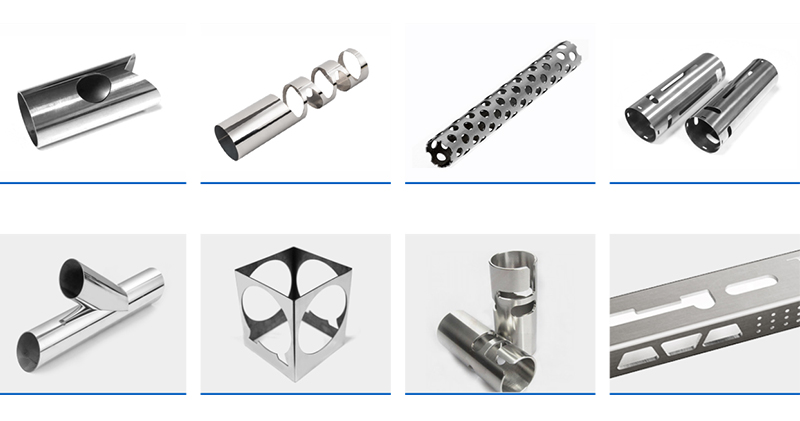

Multi-functional cutting

- Applicable types of tubes: Round, Square, Rectangular, Oval

- Applicable types of cutting: Holes cutting, Angle cutting, Arc cutting, Letters & patterns cutting…

- Applicable types of material: Stainless steel, Carbon steel, Galvanized steel, Brass, Aluminum, Copper…

- Ultra-rapid speed, smooth and burr-free cutting.

Simultaneously loading and cutting

- 6 feeding rollers clamp the pipe, feeding cycle does not need to be reset, reducing the waiting time and greatly improving the cutting efficiency

LX Self-developed system

- With United Kingdom RADTUBE nesting software, easy to operate, stable performance

| Model No. | LX-K6 |

| Outside Diameter | 15-60mm |

| Square Diameter | 15*15-60*60mm |

| Tube Length | 4000-6200mm |

| Laser Power | 1000-2000W |

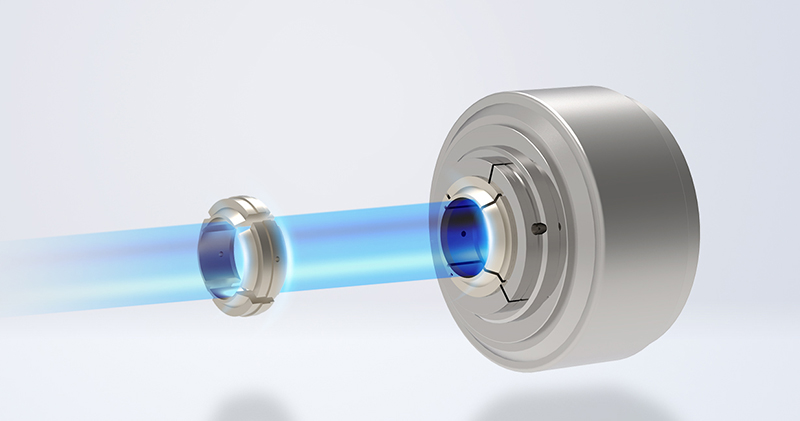

| Laser Source | MAX |

| Laser Head | RAYTOOLS |

| L*W*H (mm) | 9200*2000*1800 |

| Machine weight | 4 Tons |

| Tail material length | 40-60mm |

| Voltage | 380V 50Hz 3Phase (can be customized) |

| Control System | LX LASER |

| Air pressure | 1.6 - 3.0 MPa |

| Nesting Software | RADTUBE / United Kingdom |

| Servo motor & driver | DELTA / Taiwan |

| Reducer | FASTON / Taiwan |

| Pneumatic system | AIRTAC / Taiwan |

| Electrical proportional valve | SMC / Japan |

| Electrical components | SCHNEIDER / France |

| Gear rack | FASTON / Taiwan |

| Rail | PMI / Taiwan |

1.Can K6 be manually loaded?

The new economic model may have a manual solution, but the standard K6 is not supported

2. Ignoring the loading, can K6 cut angle steel, H-shaped profile, and U-shaped profile?

Ignoring the loading, K6 can cut special shaped profiles, but this involves the problem of the loading system, K6 standard configuration does not support.

3.Can K6 be equipped with a protective device on the roller system?

Safety measures can be installed, such as protective covers, etc., without affecting maintenance

4.In addition to Chinese and English, can K6 support other languages?

Supporting Japanese, Korean, German, Spanish, Russian, French, Portuguese, Italian, Thai, just need to translate the corresponding language, then import into the system.

5.How long can the shortest and longest be cut?

Standard 1000-2000mm, a supporting material device can be added for more than 2.5 meters, and it can be cut to 6 meters.

6. How and what needs to be maintained, how often, which areas need lubrication, what kind of oil needs to be used and so on?

Basically, just need to keep the machine clean & tidy by removing the dust & scraps around the machine, so as to keep frequent operation.

In addition, there are 2 parts need to fill lubricating oil (feed to laser cutting components and loading components).

Just check if there is enough oil in these two boxes every shift before starting the machine.

The oil is JIS K2213 or ISO Vg32 or at the same level, specially for lubricate pneumatic parts.

It is easy to find at the market.

One more part needs to brush butter is the feeding roller device, brushing frequency depends on using condition. Don’t have to brush frequently.

7.How clean the steel tubes must be in order to work with the laser cutting machine?

For most of our customers who are cutting steel pipes, their pipes have oil on it, the main purpose is to prevent rust. So far, the cutting is good; no customer has said that this affects the cutting.