English

English

Features of this series:

1.Automatic feed, quick and accurate, save manpower.

2.The special designed feed mechanism is accurate and reliable, and the intermediate transport station can choose the type of the necessary type according to the outer diameter of the pipe.

3.Strong head design, power head and motor drive, head fixed. Growth knife life.

4.Use self-centering fixture to ensure the processing concentricity.

5.The whole process touch screen controls PLC, pneumatic automatic control, pneumatic clamping, pneumatic feed, simple and convenient operation.

6.End special cutter design, using normalized blade, adjust the knife is simple and convenient, the tube Angle, corner, surface finish in one time, an average of 3 to 10 seconds a (according to the size of the pipe diameter and thickness), fast efficiency.

Main techincal parameter

Model | LX-50SM |

Main motor power | 2.2KW |

| Main motor brand | guanshun motor |

| air cylinder specification | SCΦ100*125*1pice SCΦ63*60-50*2pice |

Working Pressure | MPA6-8KG |

Apply to outer diameter | Φ10—Φ50mm |

Processing length | standard 120-600mm Short 40-600mm |

Machining accuracy | ±0.05mm |

Processing speed | 4-6 s/pice |

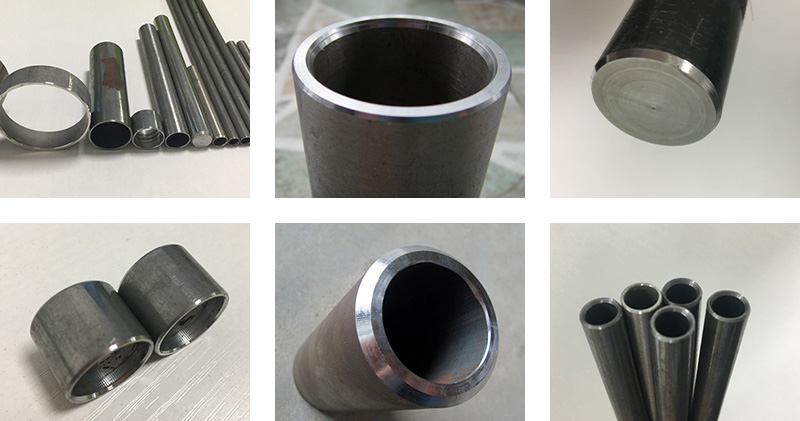

Suitable material | Steel pipe, iron pipe, stainless steel pipe, aluminum pipe, copper pipe, plastic pipe, nylon pipe, round rod |

Standard Configuration |

2 pieces of cutter disc of one machine (installed on the machine platform) Special wrench two pieces of hexagon wrench set Adjustable spanner one operating manual one blade 6 blade screw blade screw one |

Machine size | 2200x1000x1100mm |

1. Are standard inserts used in this tool holder or its customized? How many inserts can be fitted in single tool for different chamfering with different chamfering angle achievable from this single supplied tool.

The knives are standard, but the knives holders are not , then realize the different angle chamfering.

2. How offset (+/- setting) setting can be done during running operation, is it totally manual?

Manually shake the machine head to separate or close the machine head. After adjusting to the approximate position, fix the machine head, and then adjust the Rear positioning nut of the hydraulic cylinder, to adjust the accuracy and set the offset (+/- setting)

3. What is the mechanism for centring the different tube diameters?

For workpieces of different sizes, only simple replacement and adjustment of the cutter head and clamping die are required.

4.Does in your design tooling head assembly moving with box fitting or with linear guide rail bearing.

The chamfering head and machine body are dovetail guides, not linear guide.