English

English

Main Features:

1.Strong head design, power head and motor drive, head fixed. Growth knife life.

2.Use self-centering fixture to ensure the processing concentricity.

| Model | Diameter (Pipe) | Length | Diameter (Solid Bar) |

| LX-60AC | 6-60mm | >35mm | 2-18mm |

| LX-80AC | 8mm-80mm | >35mm | 2-27mm |

| LX-120AC | 30mm-120mm | >35mm | 5-35mm |

Main techincal parameter

Tube/bar length | Above 35mm |

Accuracy | ±0.02mm |

Speed | 3-5 seconds/pc |

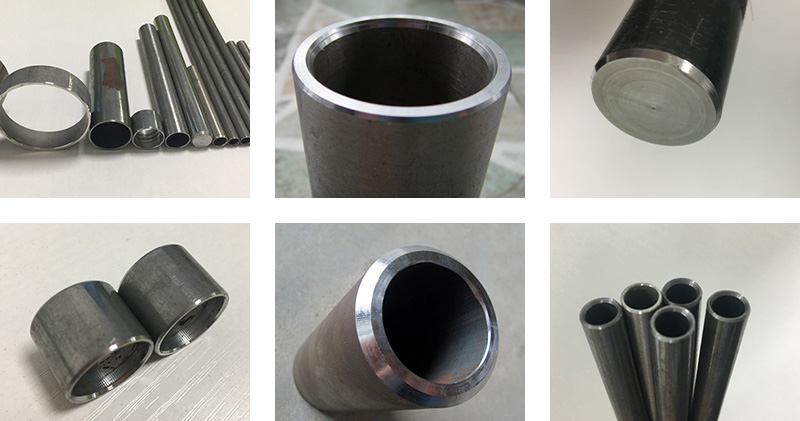

Tube/bar material | Stainless steel, carbon steel, aluminum, copper, plastic, nylon |

Including | Chamfering machine X1 set Clamp(mould) X 1 set Tools X 1 set Spare part: 3pcs blade |

Machine dimension | 900x800x1300mm |

Machine weight | 130KGS |

1. Are standard inserts used in this tool holder or its customized? How many inserts can be fitted in single tool for different chamfering with different chamfering angle achievable from this single supplied tool.

The knives are standard, but the knives holders are not , then realize the different angle chamfering.

2. How offset (+/- setting) setting can be done during running operation, is it totally manual?

Manually shake the machine head to separate or close the machine head. After adjusting to the approximate position, fix the machine head, and then adjust the Rear positioning nut of the hydraulic cylinder, to adjust the accuracy and set the offset (+/- setting)

3. What is the mechanism for centring the different tube diameters?

For workpieces of different sizes, only simple replacement and adjustment of the cutter head and clamping die are required.

4.Does in your design tooling head assembly moving with box fitting or with linear guide rail bearing.

The chamfering head and machine body are dovetail guides, not linear guide.