English

English

Stainless steel round tube, for automotive exhaust pipes manufacturing

38*1 mm stainless steel round tube, for three-way catalytic converters manufacturing

Stainless steel round tube, for automotive shock absorbers manufacturing

Brass round tube, for sanitary accessories manufacturing

One stop solution for automotive components – LX-FL120

Dedicated for round tubes

- Applicable types of tubes: outer diameter 16 -120 mm ( 0.7’’ – 4.7’’ )

- Applicable types of material: Stainless steel, Carbon steel, Galvanized steel, Brass, Aluminum, Copper…

Fully automatic in bundle loading, feeding and cutting

- Skip production processes and minimize the labor costs and consumables.

- Each machine can help save 3-5 workers comparing to saw blade cutting machine, greatly reduce the labor cost.

Automatic pipe’s head sensing and cutting

- Automatic pipe’s head and remain separate function

- The shortest tail material can be less than 40mm

High speed, smooth and burr-free cutting

- Faster than circular sawing machines, can reach less than 1 second/cut

Cutting capacity

| Material | Diameter * Thickness * Length | Cutting Capacity |

| Stainless Steel(Curtain Rods) | 15.88*0.4*1023mm | 5, 000pcs/8hours |

| Carbon Steel(Shock Absorbers) | 45*1.0*187mm | 8, 500pcs/8hours |

| The cutting capacity of 1000W laser tube cutting machine in shock absorbers manufacturing | ||

| Diameter * Thickness * Length | Cutting Capacity | Cut time(second) |

| 45*1.0*187mm | 1, 054pcs/hour | 2.2 |

| 29.4*1.2*304mm | 988pcs/hour | 2 |

| 29*1.0*172mm | 1, 088pcs/hour | 2 |

| 65*1.5*330mm | 756pcs/hour | 2.9 |

| 75*1.2*260mm | 792pcs/hour | 2.7 |

***We can evaluate the cutting capacity base on your tube information.***

Optional function

Special spatter reduced function for inner wall cleaning

- The spatter will inevitably adhere to the inner wall of tubes during the laser cut processing. Therefore, we can add an automatic spatter reduced device to ensure that the inner wall of the finished product remains clean.

* Dedust Test Report

| Cutting Gas | Dedust Function | Result |

| Nitrogen | With | Silver color, no oxidation, clean inner wall |

| Air | With | Some yellow color, has oxidation, clean inner wall |

| Air | Without | Some yellow color, has oxidation, not clean inner wall |

P.S.: Test tube size: stainless steel 304, O.D. 40 mm, W.T. 1.5 mm, Cutting Length 18 mm

Combine with chamfering machine / bending machine

- For automotive components industry, we can provide one stop solution and laser cutting production line

- The laser pipe cutting machine and the pipe chamfering machine are seamlessly connected through conveyors.

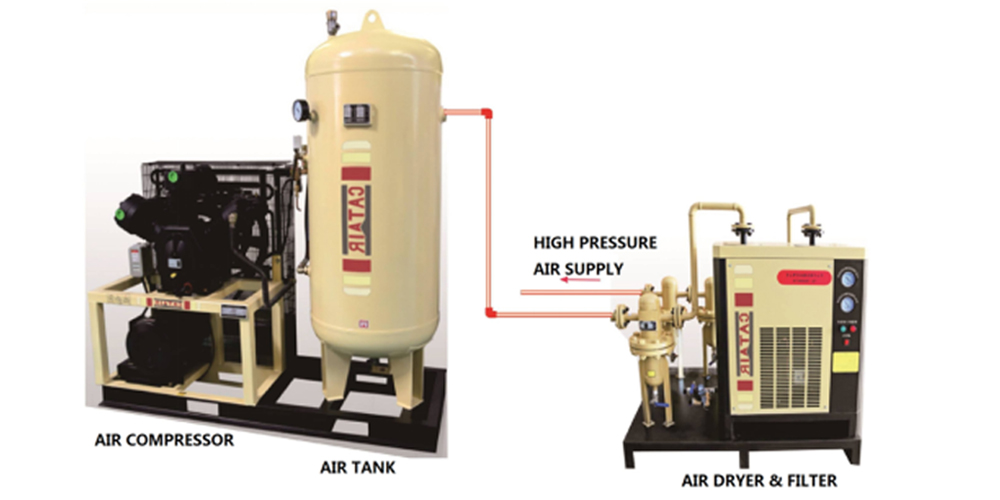

Air compressor

| Model No. | LX-FL120F(B) |

| Outside Diameter | 16-120mm |

| Cutting Length | 30-1200mm |

| Laser Power | 1000-2000W |

| Laser Source | MAX/RAYCUS/IPG |

| Laser Head | OSPRI OR SAME LEVEL |

| L*W*H (mm) | 9450*1560*1615 |

| Voltage | 380V 50Hz 3Phase (can be customized) |

| Air pressure | 1.6 - 3.0 MPa |

| Servo motor & driver | DELTA |

| Pneumatic system | AIRTEC |

| Electrical proportional valve | SMC |

| Air switch & relay | SCHNEIDER |

| Power supply | SIEMENS |

| PLC | MITSUBISHI |

1.How do you pack the machine? How does the product be shipped abroad? How can I unload the machine from the container?

The machine will be packed by package film. We will also use hooked spines to fix the machine in the container. We can send you photos of the package & loading for reference & guiding.

2. What are the spare parts of the laser cutting machine? Can I buy components as spare parts as well?

The spare parts of the machine are the nozzle and the protective lens of the laser head. You can also buy components such as PLC, Servo in stock in case of emergency hardware failure. But we offer 1 year warranty of the machine, and the components are all proved to be stable & reliable in our sales history. So there is little need to buy these components.

3.To have the tube cut length precision, it is guarantee by optical ruler or ballscrew and encoder ?

We use ballscrew & servo motor & drive to guarantee the length precision.

4. How it is the Set-up for changing the tube diameter?

It needs to change the clamp for different diameters. One clamp is only for one size of diameter. The whole procedure can be finished in 5-10 minutes. Here the video for your reference: https://youtu.be/qbwvXPYNTDM

5. Our current electrical status is xxV xxHz 3phase. Do you think this would work ok for machine?

Normally our machine can work under 380V 50-60Hz 3phase without any problems. For other voltage, we recommend customers to buy a transformer for the machine. In some regions with unstable voltage, we recommend to buy an integrated stabilizing transformer.

6. How many hours of working life has the laser? What is the spare part cost approximately?

Laser source life 100,000 hours (more than 20 years). Spare part is the protective lens and nozzle of the laser head. Each can use 2-5 months, we offer each 5pcs for spare and free of charge. For additional quantity, each cost 16USD/ pc.

7.Can you send engineer to teach the operation course or handle after-sales service? What is the cost of oversea service?

Currently we are not able to send out engineer abroad due to epidemic status. But despite of this situation, we can offer oversea service. Clients need to afford the tickets ,visa, accommodation and 120USD per day. For example, usually it will take 5-7 days to finish the teaching of operation course, including 1 day for installation and others for training.

8. Is there a difference between MAX / RAYCUS / IPG?

The quality of lasers made in China is gradually mature and stable. According to our testings, Max and Raycus are similar in performance. IPG is rarely used in the market within 6KW, unless customers concern on the brand and do not care about the cost. This is because IPG does not show obvious difference from the other two within 6KW power.The share of IPG lasers in China is also declining year by year, in 2018 was 48% and went down to 30% 2019. The share of Max and Raycus are similar, both about 20%.In addition, the laser source is only one part of the machine. Customers should pay more attention on the performance and efficiency of the whole equipment.

9. Can we send you sample of our pipe in order for you to show us cutting of our material?

Yes, we always welcome customer send us their pipe for testing. Kindly send us pipe length ≥600mm, qty ≥ 3pcs for each size. The longer size and the more quantity the better.

10. What is the material loss every time laser cuts? I mean, when laser is cutting what is the length waste for every cut?

The laser cutting loss is very small, only 0.05-0.1mm/cut, while saw cutting loss would be about 2-5mm/cut.