English

English

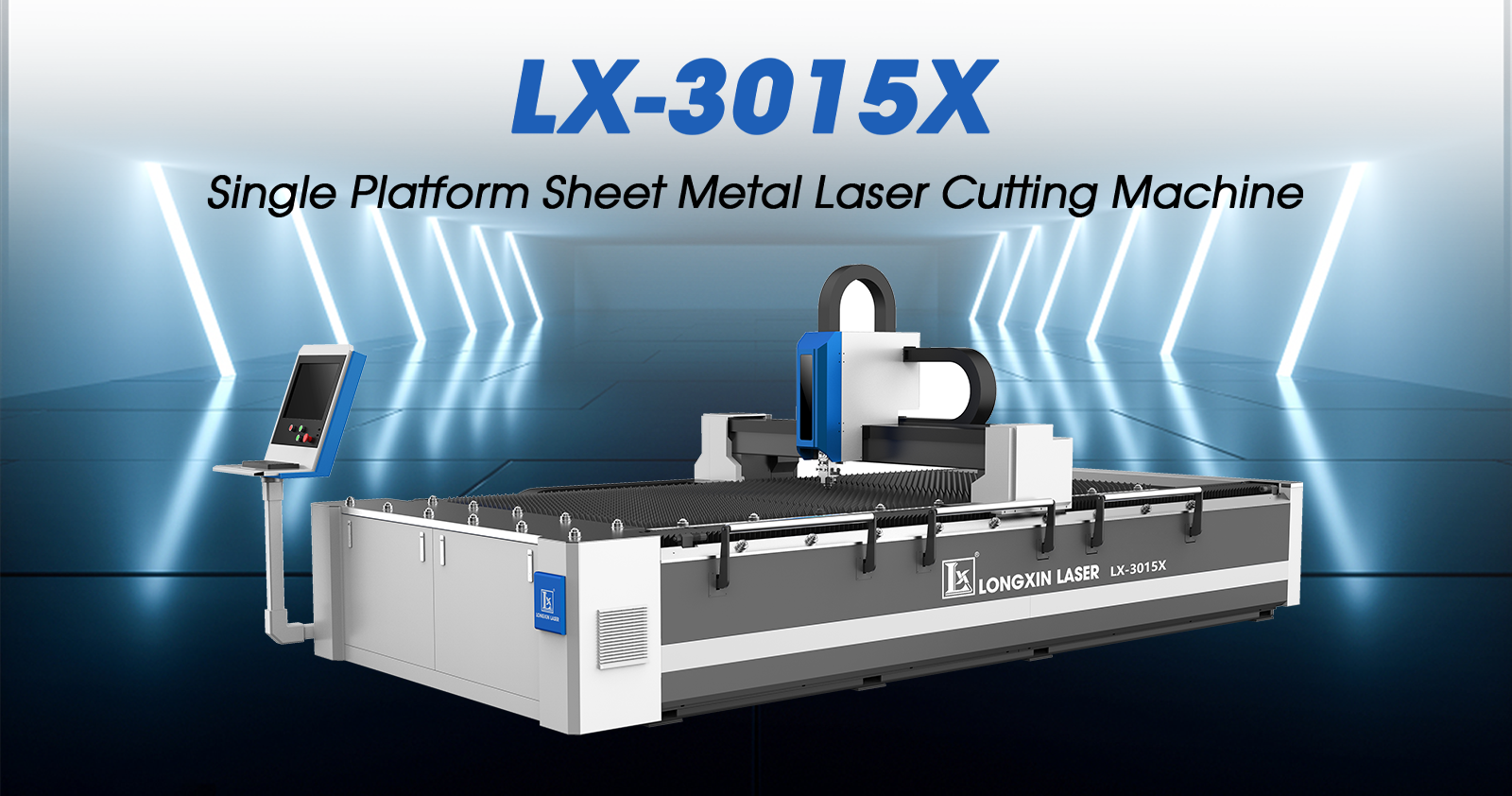

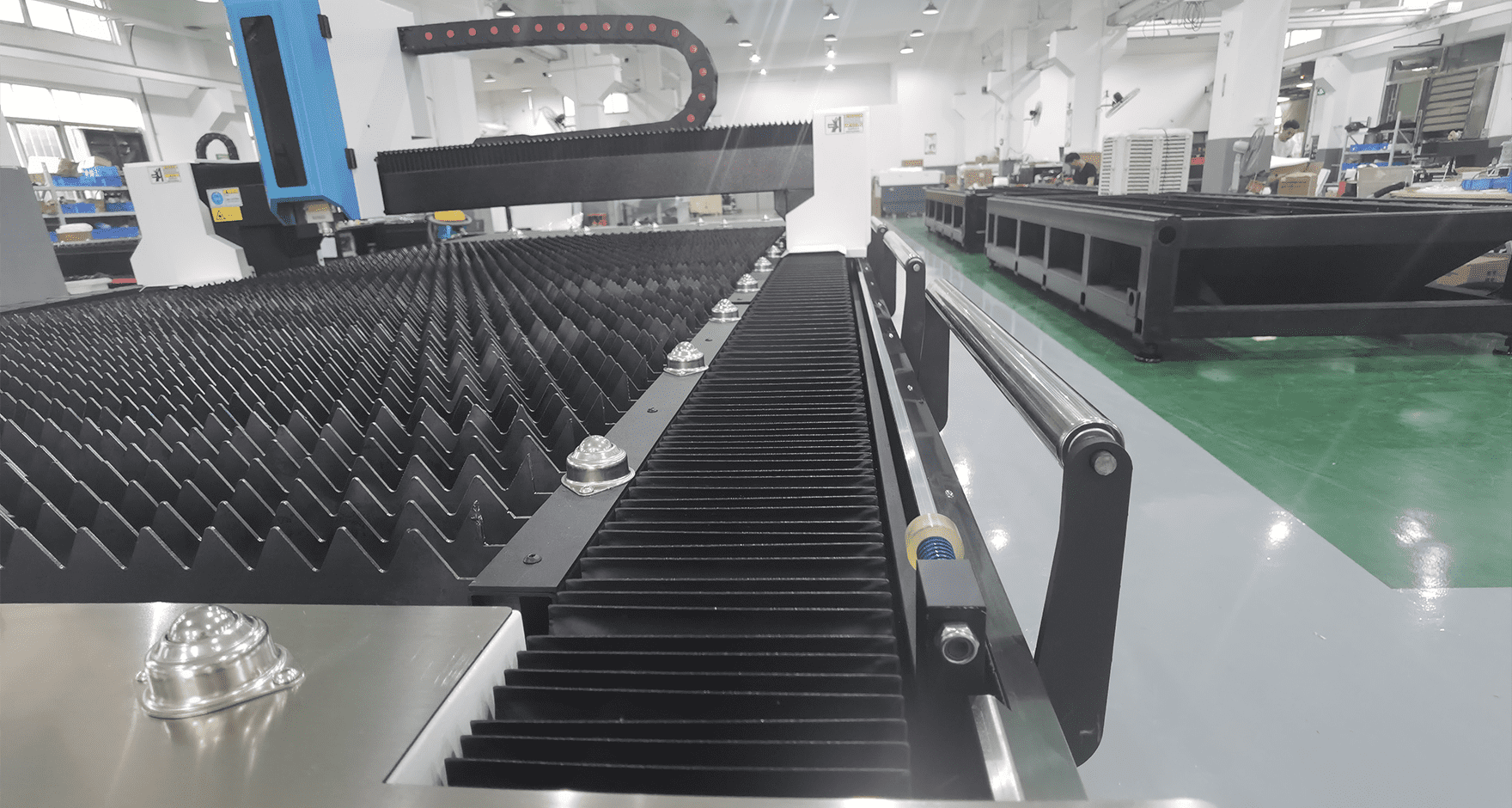

Ultra-rapid speed cutting, specially designed for furniture industry – LX-3015X

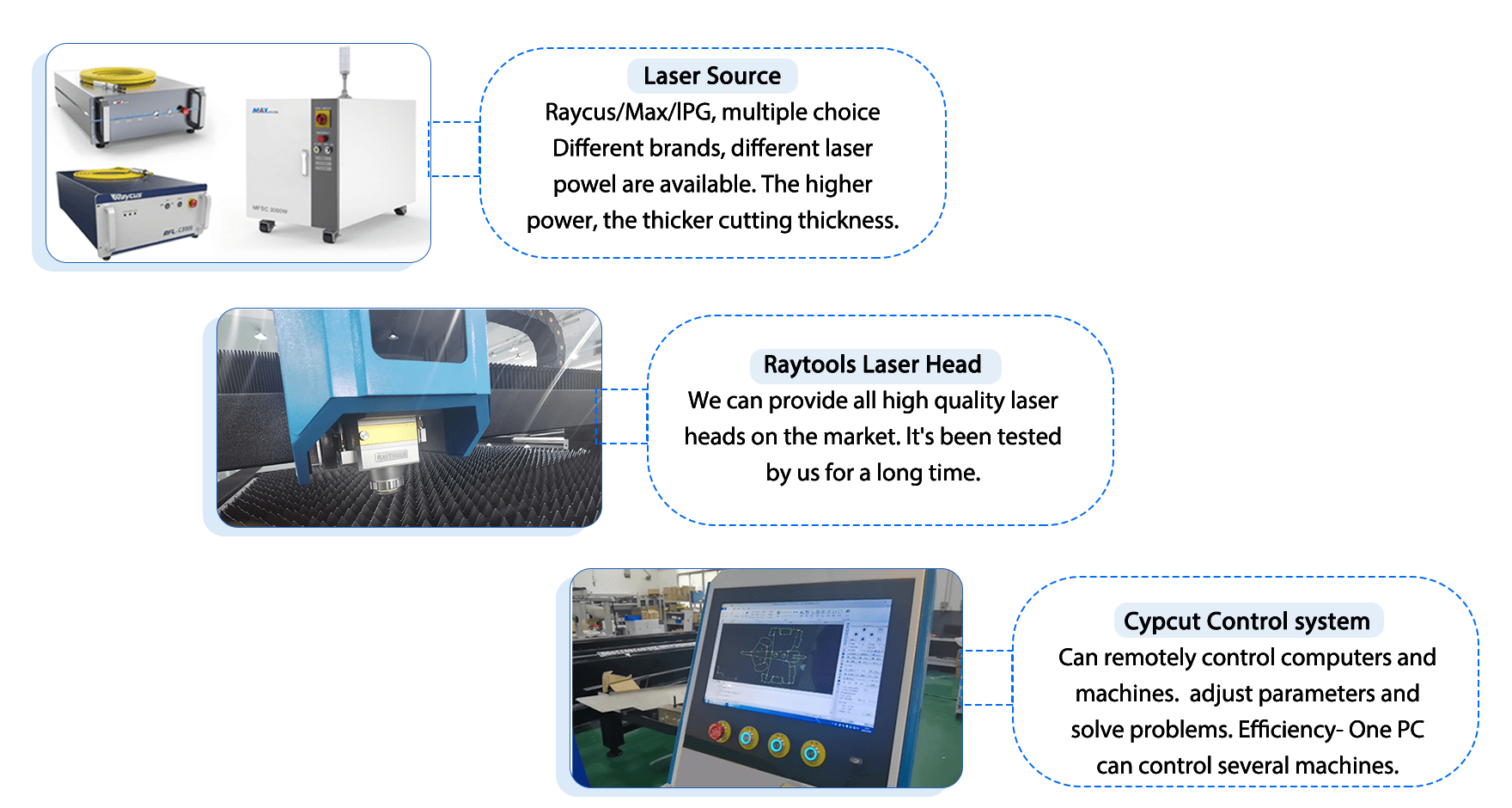

Simple Operation

—— Designed to be user-friendly, LX Laser ensures that operators can quickly adapt to the machine.

—— With intuitive controls and a user-friendly interface, the LX-3015X simplifies the cutting process, making it suitable for users of all skill levels.

—— This innovative solution has the potential to revolutionize traditional sheet metal processing methods.

Superior Processing Efficiency

Outperforming traditional cutting machines in speed and precision, the LX-3015X is equipped with advanced laser technology, significantly reducing production time and maximizing productivity.

Environmental Sustainability

—— Its zoning exhaust system minimizes air pollution, aligning with your company's commitment to environmental practices.

—— By choosing the LX-3015X, you can optimize your manufacturing processes while minimizing the impact on the environment.

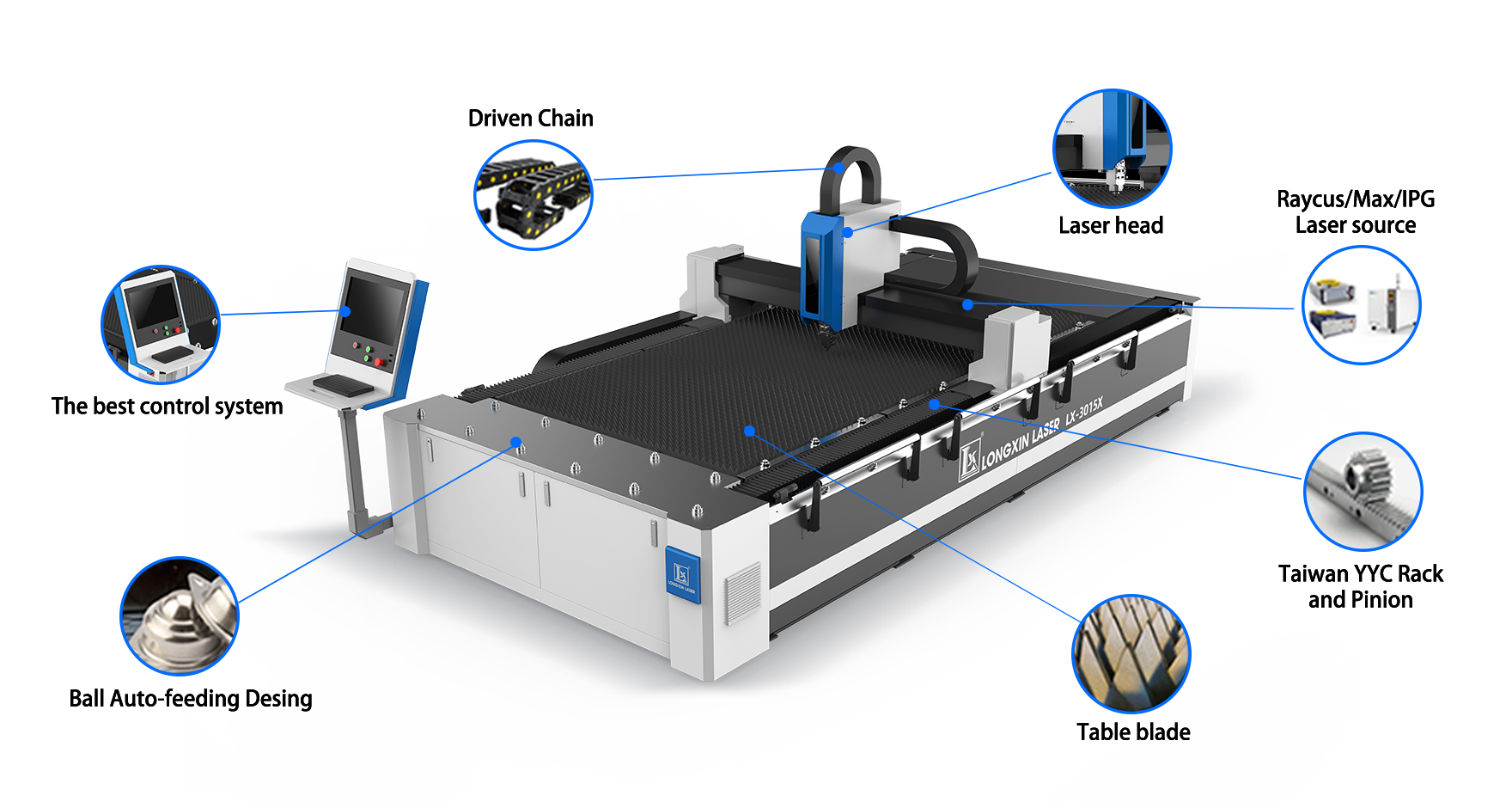

Cast Aluminum Beam

Providing exceptional rigidity, strength, and lightweight characteristics, the LX-3015X ensures the machine's capability to operate at high speeds and deliver optimal performance.

Integrated Electrical Cabinet

Maximizing floor space, reducing transportation costs, simplifying after-sales maintenance, and meeting the demands of overseas customers seeking ideal equipment solutions.

| Model | LX-3015X |

|---|---|

| Power | 1000-3000W |

| Working Sheet | 1500*3000mm/1500*4000mm |

| Repeat Position Angle | 土0.05mm |

| Working speed | 55m/min(3000WCutting1mm SS) |

| Acceleration | 1G |

| Power demand | 380V/50HZ/60HZ/63A |

| Machine weight | 3600kg |

| Apparent size | 4500*2300*1700mm |

1.Can LX-3015X be manually loaded?

The new economic model may have a manual solution, but the standard LX-3015X is not supported

2. Ignoring the loading, can LX-3015X cut angle steel, H-shaped profile, and U-shaped profile?

Ignoring the loading, LX-3015X can cut special shaped profiles, but this involves the problem of the loading system, LX-3015X standard configuration does not support.

3.In addition to Chinese and English, can LX-3015X support other languages?

Supporting Japanese, Korean, German, Spanish, Russian, French, Portuguese, Italian, Thai, just need to translate the corresponding language, then import into the system.

4. How and what needs to be maintained, how often, which areas need lubrication, what kind of oil needs to be used and so on?

Basically, just need to keep the machine clean & tidy by removing the dust & scraps around the machine, so as to keep frequent operation.

In addition, there are 2 parts need to fill lubricating oil (feed to laser cutting components and loading components).

Just check if there is enough oil in these two boxes every shift before starting the machine.

The oil is JIS K2213 or ISO Vg32 or at the same level, specially for lubricate pneumatic parts.

It is easy to find at the market.

One more part needs to brush butter is the feeding roller device, brushing frequency depends on using condition. Don’t have to brush frequently.

5.How clean the steel tubes must be in order to work with the laser cutting machine?

For most of our customers who are cutting steel pipes, their pipes have oil on it, the main purpose is to prevent rust. So far, the cutting is good; no customer has said that this affects the cutting.